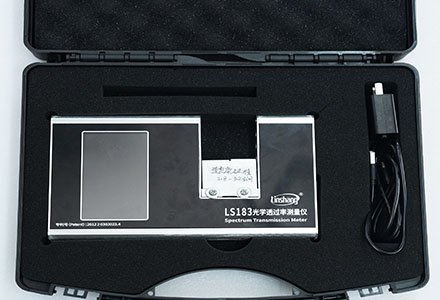

FSW Liquid Cold Plate

Leak-proof cooling with internal channels via solid-state friction welding.

The FSW Liquid Cold Plate is a critical component in modern cold plate cooling systems, designed to efficiently dissipate heat from high-power electronic devices through liquid cooling. Its working principle involves processing metal sheets to form precise flow channels, onto which electronic components are mounted with a thermal conductive interface. Coolant enters the inlet, flows across the plate, and exits through the outlet, carrying heat away while maintaining optimal device temperature. This approach ensures quiet operation, stable cooling, and minimal dependence on ambient conditions, making it ideal for sensitive applications.

A well-engineered liquid cold plate design is essential for maximizing heat transfer efficiency. The performance of the cold plate liquid cooling system depends directly on the coolant flow rate, which is influenced by the power of the liquid cooling system components. With the high heat capacity of water or other suitable liquids, these systems can handle substantial thermal loads, providing reliable cooling in demanding environments.

Custom liquid cold plate solutions allow tailored designs to meet specific industrial requirements. Liquid cooling manufacturers provide various types of liquid cooling systems, including industrial liquid cooling and liquid cooling for electronics, enabling optimized thermal management for medical equipment, new energy systems, industrial automation, and communication devices.

Partnering with expert liquid cooling manufacturers like KINGKA ensures your cold plate liquid cooling solution is efficient, durable, and precisely engineered. KINGKA provides custom FSW liquid cold plate services, using advanced technology to seamlessly weld the cooling channels with aluminum or copper base plates, ensuring excellent heat dissipation and structural strength. Strict quality control and high-standard manufacturing guarantee reliable performance and fast delivery, helping extend component lifespan, improve system performance, and maintain stability in high-demand applications.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018