The modern shipbuilding industry relies heavily on high-performance electronic and power systems to ensure safe, efficient, and reliable operation of vessels. Systems such as navigation modules, radar and communication equipment, propulsion electronics, energy storage units, and onboard computing systems generate substantial heat during operation. Without proper thermal management, this heat can lead to performance degradation, shortened component lifespan, and potential system failures. Kingka’s Liquid Cold Plates and heat sinks provide efficient, reliable, and customized thermal management solutions specifically designed for the shipbuilding industry.

Liquid Cold Plates for Shipboard Systems

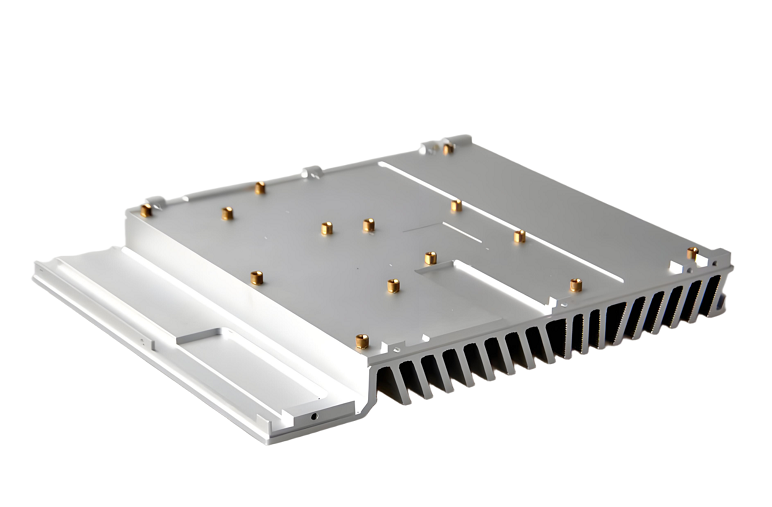

Kingka offers a wide range of Liquid Cold Plates, including FSW Liquid Cold Plates, Tube Liquid Cold Plates, and Brazed Liquid Cold Plates, engineered to meet the unique cooling requirements of maritime electronics and high-power shipboard devices.

Key Advantages:

Optimized Cold Plate Design – Ensures uniform heat distribution across sensitive components such as IGBTs, power converters, and propulsion controllers.

High-Efficiency Heat Dissipation – Integration with water cooling circuits and industrial water cooling systems provides precise temperature control even under heavy load.

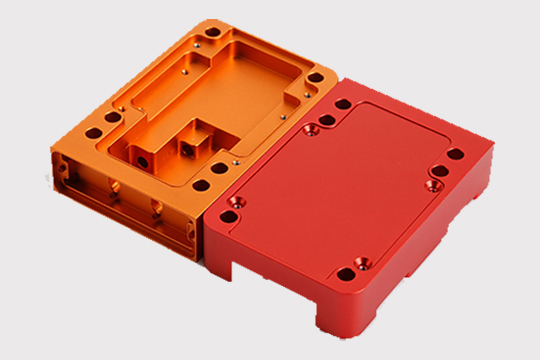

Flexible Customization – Supports small cold plates, standard cold plates, and tube cold plates, allowing adaptation to compact or irregular shipboard layouts.

Enhanced Electronics Cooling – Maintains stable operating temperatures for sensitive onboard systems, improving reliability in harsh marine environments.

Liquid Cold Plates are widely applied in:

Propulsion inverter and power electronics modules

Energy storage and battery thermal management

High-power radar, sonar, and communication systems

Onboard servers and computing modules

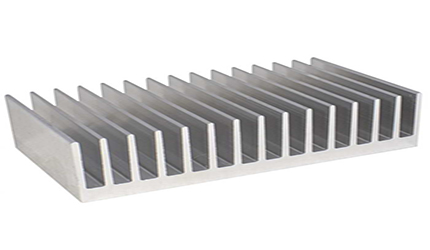

Heat Sinks for Shipboard Electronics

In addition to liquid cooling, Kingka provides a diverse range of Heat Sinks to further enhance thermal management of shipboard electronics. Products include aluminum heat sinks, copper heat sinks, extruded heat sinks, and water cooled heat sinks.

Advantages of Kingka Heat Sinks:

Superior Thermal Conductivity – Aluminum and copper designs optimize heat transfer from high-power modules.

Integration with Water Cooling – Supports heat sink with water cooling or liquid cooled heat sink setups for high-density electronics.

Customizable Designs – Includes fin designs, extruded plates, and flexible heat sinks tailored to specific system requirements.

Enhanced Component Reliability – Reduces thermal stress on critical electronics, extending lifespan and maintaining operational stability.

Heat Sinks are commonly applied in:

Navigation and communication electronics

Radar and sensor control modules

Propulsion controllers and converters

High-performance computing systems on board

Applications and Benefits in Shipbuilding

Kingka’s Liquid Cold Plates and Heat Sinks help marine engineers address key challenges in ship thermal management:

High-Power Propulsion Systems – Efficiently dissipate heat from inverters and motor drives, ensuring stable operation under continuous heavy load.

Navigation and Communication Equipment – Maintain optimal temperature for radar, sonar, and radio systems, avoiding signal drift and equipment failure.

Energy Storage and Power Management – Precisely control battery module temperatures, improving energy efficiency and safety.

Onboard Electronics and Computing – Reduce thermal stress on servers and controllers, supporting long-term system reliability.

By maintaining precise operating temperatures, Kingka’s thermal solutions enhance system efficiency, reliability, and safety, even in the harsh marine environment characterized by high humidity, vibration, and temperature fluctuations.

Why Kingka

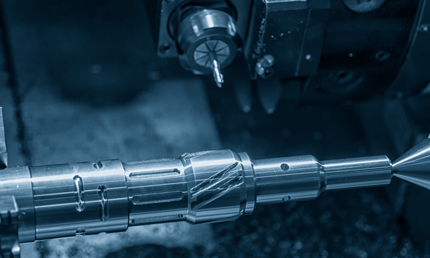

With decades of expertise in thermal management technology, Kingka delivers custom Liquid Cold Plates and Heat Sinks tailored for shipbuilding applications. Our solutions provide:

Precise thermal control for high-power electronics

Reliable cooling under harsh marine conditions

High efficiency and long-term stability

Integration with water cooling systems and industrial cooling circuits

Kingka’s products help shipbuilders and marine engineers achieve optimal performance, safety, and longevity for critical onboard systems.