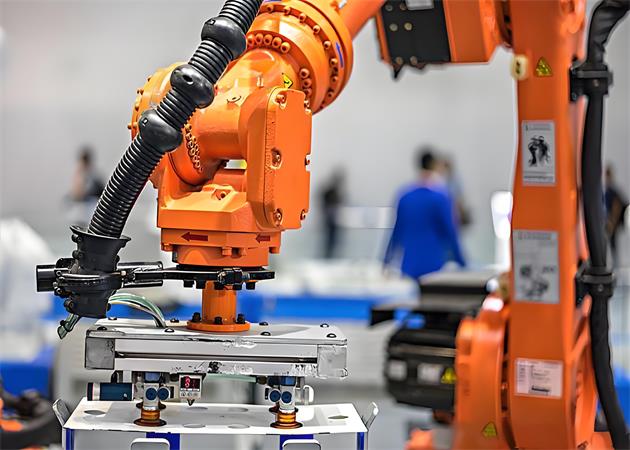

The automation industry relies on highly integrated control systems, robotics, industrial sensors, and high-power electronic modules to achieve precision, efficiency, and reliability. These systems generate substantial heat during operation, which can negatively affect performance and longevity if not managed properly. Kingka’s Liquid Cold Plates and heat sinks provide efficient and reliable thermal management solutions for automation equipment.

Liquid Cold Plates for Automation Equipment

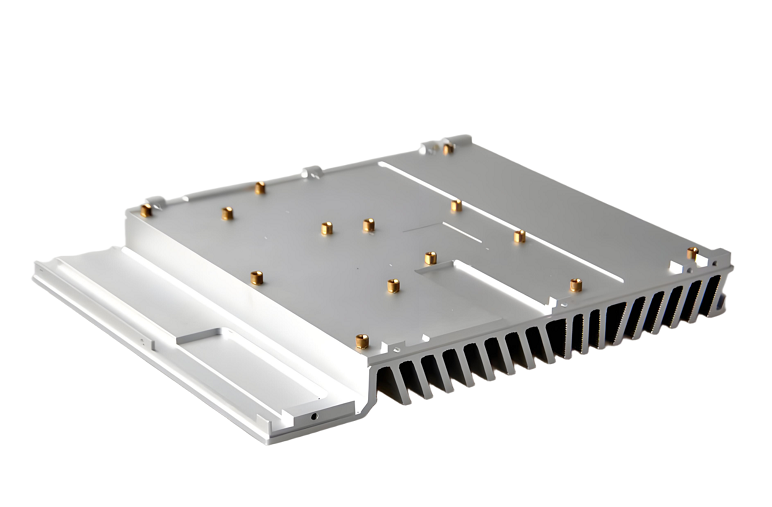

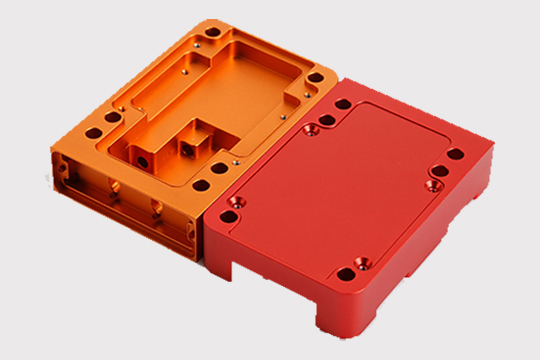

Kingka offers a wide range of Liquid Cold Plates, including FSW Liquid Cold Plates, Tube Liquid Cold Plates, and Brazed Liquid Cold Plates, engineered to handle high heat flux in automated industrial systems.

Key Advantages:

Optimized Cold Plate Design – Uniformly dissipates heat from high-power modules such as PLC units, motor drivers, and industrial controllers.

Integration with Water Cooling Systems – Compatible with water cooling circuits, industrial water cooling systems, and water cooled electronics for precise temperature control.

Customizable Solutions – Offers small cold plates, standard cold plates, and tube cold plates suitable for compact or specialized automation equipment layouts.

Enhanced Electronics Cooling – Maintains stable operating temperatures, improving reliability and reducing thermal stress on sensitive components.

Applications of Liquid Cold Plates in automation include:

High-power industrial robotics and servo drives

PLC and industrial controller thermal management

Automated manufacturing equipment and testing systems

Power modules and converters in factory automation

Heat Sinks for Automation Systems

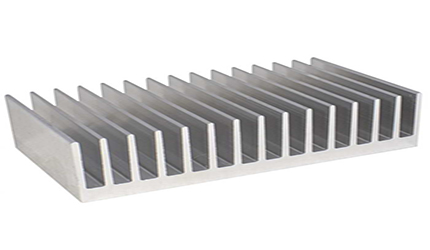

In addition to liquid cooling, Kingka provides a wide range of Heat Sinks, including aluminum heat sinks, copper heat sinks, extruded heat sinks, and water cooled heat sinks, for supplementary cooling of automation electronics.

Advantages of Kingka Heat Sinks:

Efficient Heat Dissipation – Optimized heat sink design and heat sink fin design for high-power industrial components.

Flexible Integration – Supports heat sink with water cooling or liquid cooled heat sink designs.

Custom Engineering – Solutions for industrial heat sinks, high-performance heat sinks, and liquid cooled electronics.

Enhanced Component Reliability – Reduces thermal stress, extends lifespan, and maintains operational stability for automation devices.

Heat sinks are commonly applied in:

Servo drives and motor controllers

Industrial PLCs and robotics

Power converters and drives for factory automation

Automated testing and measurement systems

Applications and Benefits in Automation

Kingka’s Liquid Cold Plates and Heat Sinks help automation engineers address key challenges:

Precision Temperature Control – Maintain optimal temperatures for high-power electronics in robotics and automated machinery.

High Reliability – Prevents thermal-induced failures in PLCs, sensors, and motor drivers.

Extended Component Lifespan – Reduces thermal stress for electronics operating under continuous industrial workloads.

Integration Flexibility – Supports both compact and high-density layouts in modern automation systems.

By providing efficient and precise thermal management, Kingka’s solutions enhance the performance, reliability, and operational efficiency of automated systems in factories, industrial plants, and research facilities.

Why Kingka

With extensive expertise in thermal management technology, Kingka delivers customized Liquid Cold Plates and Heat Sinks for the automation industry, ensuring:

Precise and uniform cooling for high-power electronics

Reliable operation under continuous workloads

Integration with industrial water cooling systems and water cooling circuits

Optimized heat dissipation for compact or high-density setups

Kingka’s thermal solutions empower automation equipment to achieve maximum efficiency, stability, and safety, supporting advanced manufacturing and industrial control systems.