High-power industrial laser systems are characterized by high heat flux and precise operational requirements. Effective thermal management is critical to maintain stability, performance, and longevity of laser components. Kingka’s Liquid Cold Plates and heat sinks provide reliable and efficient cooling solutions for laser equipment, ensuring optimal operation under demanding conditions.

Liquid Cold Plates for Laser Equipment

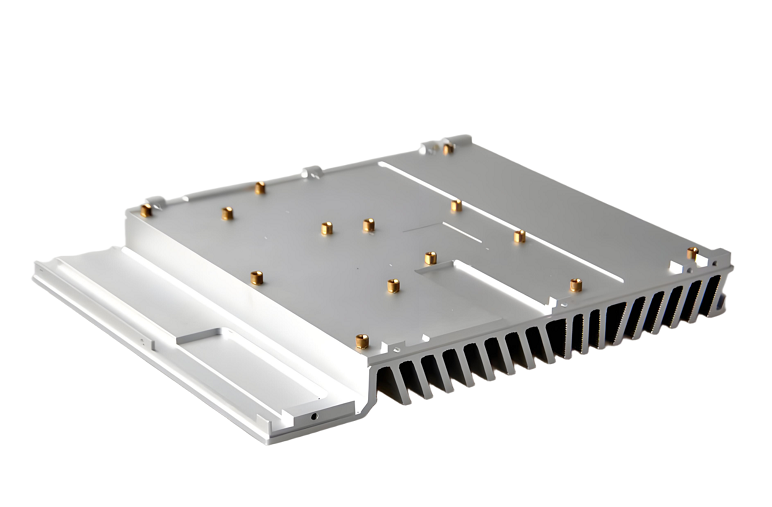

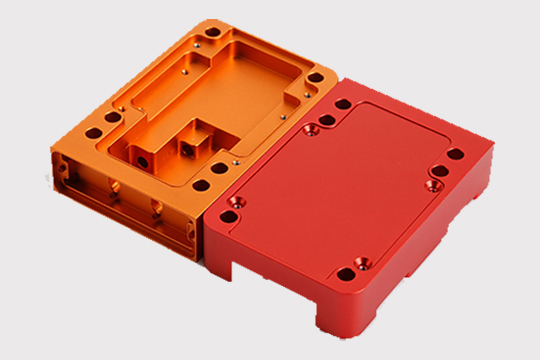

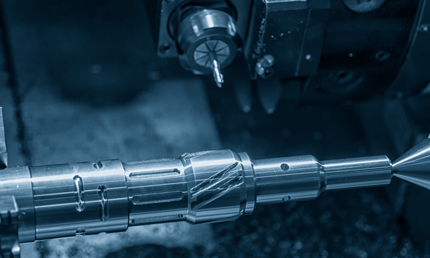

Kingka’s Liquid Cold Plates — including FSW Liquid Cold Plates, Tube Liquid Cold Plates, and Brazed Liquid Cold Plates — are designed to dissipate heat from key laser components such as laser crystals, pump sources, and high-power optical modules.

Key features include:

Precision cold plate design for uniform heat transfer

Integration with water cooling circuits and water cooling systems for industry

Custom options such as small cold plates, standard cold plates, and tube cold plates for compact laser setups

Enhanced cold plate electronics cooling to prevent thermal drift and maintain beam quality

Heat Sinks for Laser Equipment

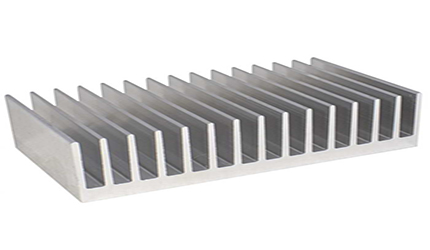

In addition to liquid cooling, Kingka provides a wide range of Heat Sinks, including aluminum heat sinks, copper heat sinks, extruded heat sinks, and water cooled heat sinks, for additional thermal management of laser driver electronics and supporting modules.

Advantages of Kingka heat sinks in laser applications:

Optimized heat sink design and heat sink fin design for efficient thermal dissipation

Compatibility with heat sink with water cooling or liquid cooled heat sink setups

Improved heat sink efficiency and reduced thermal stress for sensitive electronic components

Applications in Laser Equipment

Kingka’s Liquid Cold Plates and Heat Sinks are widely used in:

High-power industrial laser systems

Fiber lasers and CO₂ lasers

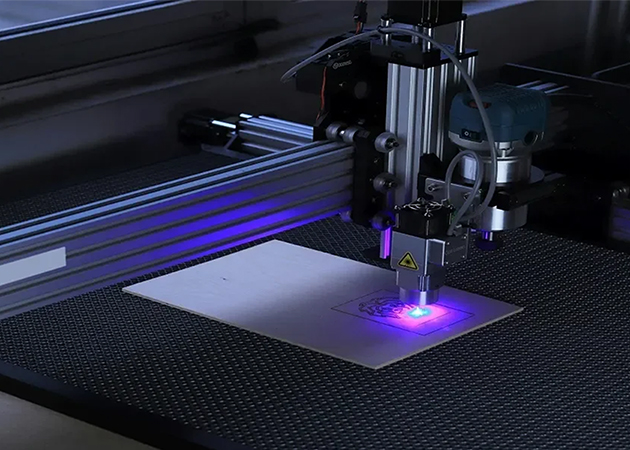

Laser cutting, welding, and engraving machines

Laser pump modules and driver electronics

By maintaining precise temperatures, Kingka’s thermal solutions enhance laser stability, beam quality, and component longevity, which are critical for high-performance industrial laser applications.

Why Kingka

With advanced expertise in thermal management technology, Kingka delivers customized Liquid Cold Plates and Heat Sinks for the laser equipment industry. Our solutions ensure precise, efficient, and reliable cooling for high-power lasers, supporting superior performance and operational safety.