As photovoltaic systems evolve to higher power densities and larger capacities, effective thermal management becomes critical to ensure efficiency, safety, and long-term stability. Kingka’s Liquid Cold Plates and heat sinks provide high-performance cooling solutions for photovoltaic inverters, solar modules, and energy storage systems.

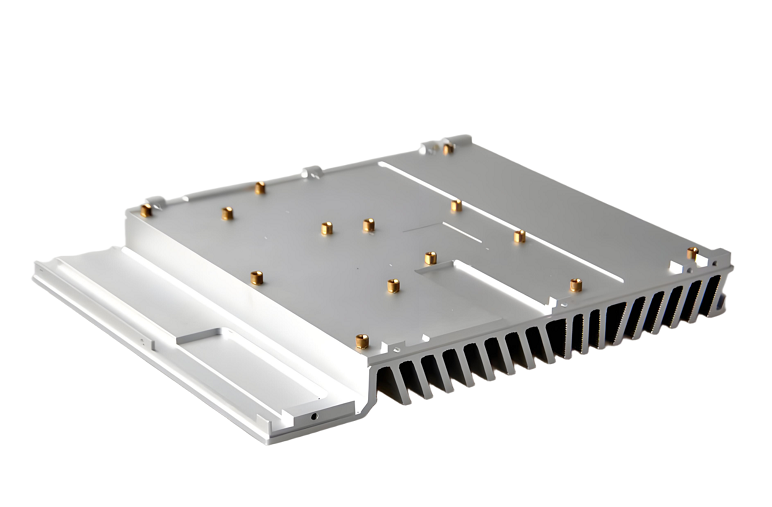

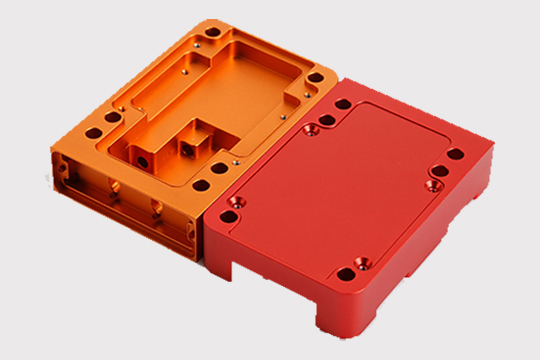

Liquid Cold Plates for Photovoltaic Applications

Kingka offers a wide range of Liquid Cold Plates, including FSW Liquid Cold Plates, Tube Liquid Cold Plates, and Brazed Liquid Cold Plates, specifically designed to manage heat in high-power string and centralized inverters.

Key benefits include:

Efficient heat removal from IGBTs and power modules, maintaining optimal operating temperatures.

Integration with water cooling circuits and water cooling systems for industry, providing precise thermal control in outdoor environments.

Flexible designs such as small cold plates, standard cold plates, and tube cold plates, suitable for compact inverter layouts.

Enhanced cold plate electronics cooling to ensure reliable inverter performance under continuous high load.

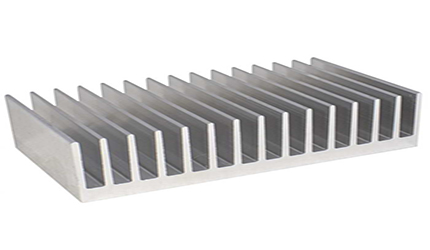

Heat Sinks for Photovoltaic Systems

In addition to liquid cooling, Kingka Heat Sinks provide reliable air and liquid-assisted thermal management for solar inverters and associated electronics. Our products include aluminum heat sinks, copper heat sinks, extruded heat sinks, and water cooled heat sinks, enabling efficient dissipation of heat from high-power components.

Advantages of Kingka heat sinks in photovoltaic applications:

Optimized heat sink design for maximum surface area and reduced thermal resistance

Options for heat sink with water cooling, heat sink with heat pipe, or liquid cooled heat sink integration

Support for industrial heat sinks, high-performance heat sinks, and customized designs for specific inverter configurations

Improved system efficiency and extended component lifespan

Applications in Photovoltaic Systems

Kingka’s Liquid Cold Plates and Heat Sinks are widely used in:

High-power string inverters and medium-to-large centralized inverters

Battery management and energy storage converters

Solar power electronics modules

Wind-to-solar hybrid energy systems

By maintaining optimal temperatures, our thermal solutions enhance energy conversion efficiency, reduce thermal stress, and ensure long-term reliability of photovoltaic equipment.

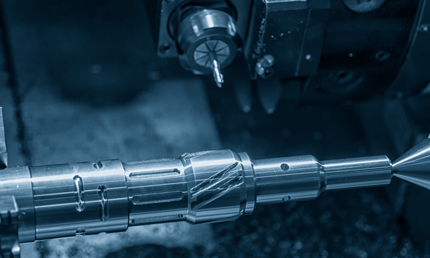

Why Kingka

With expertise in thermal management technology, Kingka delivers tailored Liquid Cold Plates and Heat Sinks to meet the demanding requirements of the photovoltaic industry. Our advanced cold plate cooling solutions, water cooled heat sinks, and heat sink with water cooling systems provide precise, efficient, and reliable thermal management for modern solar energy systems.