High-power lighting systems, including LED floodlights, stage lighting, architectural lighting, and industrial luminaires, generate substantial heat during operation. Without proper thermal management, excessive heat can reduce LED efficiency, shorten lifespan, and affect color stability. Kingka’s Liquid Cold Plates and heat sinks provide reliable, high-efficiency cooling solutions, ensuring optimal performance for modern lighting systems.

Liquid Cold Plates for Lighting Applications

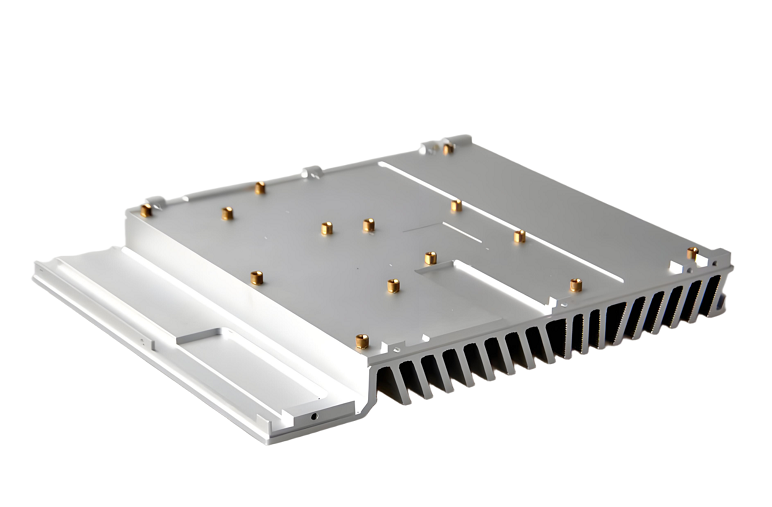

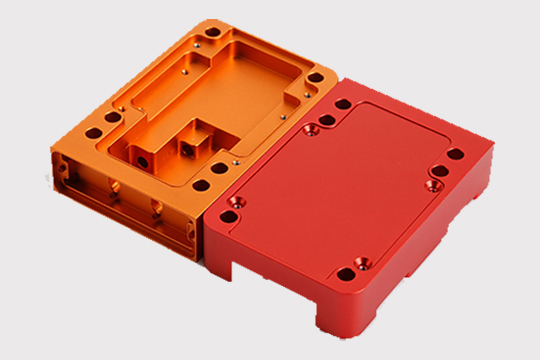

Kingka offers a range of Liquid Cold Plates, including FSW Liquid Cold Plates, Tube Liquid Cold Plates, and Brazed Liquid Cold Plates, designed to dissipate heat from high-density LED arrays and power electronics.

Key Advantages:

Optimized Cold Plate Design – Ensures uniform heat distribution for LED modules and driver circuits.

High-Efficiency Cooling – Integration with water cooling circuits and industrial water cooling systems provides precise temperature control, extending LED lifespan.

Custom Solutions – Supports small cold plates, standard cold plates, and tube cold plates suitable for compact or specialized lighting setups.

Enhanced Electronics Cooling – Protects sensitive driver components and ensures stable light output under continuous operation.

Applications of Liquid Cold Plates in Lighting:

High-power LED luminaires

Stage and studio lighting systems

Architectural and outdoor floodlights

Industrial and warehouse lighting

Heat Sinks for Lighting Systems

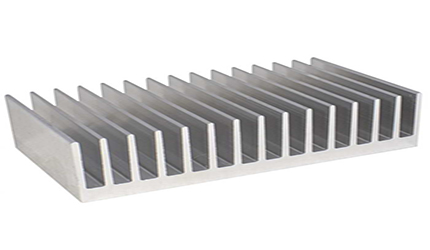

In addition to liquid cooling, Kingka provides a wide range of Heat Sinks, including aluminum heat sinks, copper heat sinks, extruded heat sinks, and water cooled heat sinks, to manage thermal loads in high-power lighting.

Advantages of Kingka Heat Sinks:

Efficient Heat Dissipation – Optimized heat sink design and fin structures remove heat effectively from LEDs and power drivers.

Flexible Integration – Supports heat sink with water cooling or liquid cooled heat sink designs for high-power applications.

Customized Engineering – Solutions for industrial heat sinks, high-performance LED heat sinks, and liquid cooled electronics.

Improved Reliability – Reduces thermal stress, ensuring consistent light output and long operational lifespan.

Heat Sink Applications in Lighting:

LED floodlights and spotlights

High-bay industrial lighting

Stage lighting and professional studio setups

Outdoor and architectural lighting fixtures

Benefits for the Lighting Industry

Kingka’s Liquid Cold Plates and Heat Sinks address key thermal challenges in lighting:

Enhanced LED Efficiency – Maintain optimal operating temperatures for maximum luminous efficacy.

Extended Lifespan – Reduce thermal degradation of LED chips and driver electronics.

Stable Performance – Ensure consistent light color and intensity under continuous operation.

Design Flexibility – Integrate compact or high-density cooling solutions for modern lighting designs.

Why Kingka

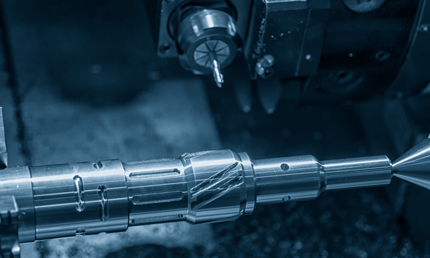

With extensive expertise in thermal management technology, Kingka delivers custom Liquid Cold Plates and Heat Sinks tailored for the lighting industry. Our solutions provide:

Precise thermal control for high-power LED modules

Reliable operation under continuous lighting loads

Integration with water cooling circuits and systems

Optimized heat dissipation for compact or specialized lighting setups

Kingka’s thermal solutions empower lighting manufacturers to achieve high efficiency, reliability, and long-lasting performance in both commercial and industrial lighting applications.