The semiconductor industry is a high-precision and high-power sector where effective thermal management is critical. Devices such as power modules, CPUs, GPUs, photolithography equipment, and high-density chip assemblies generate significant heat during operation. Excess heat can compromise performance, reduce efficiency, and shorten component lifespan. Kingka’s Liquid Cold Plates and heat sinks provide precise, reliable, and high-efficiency cooling solutions for these demanding applications.

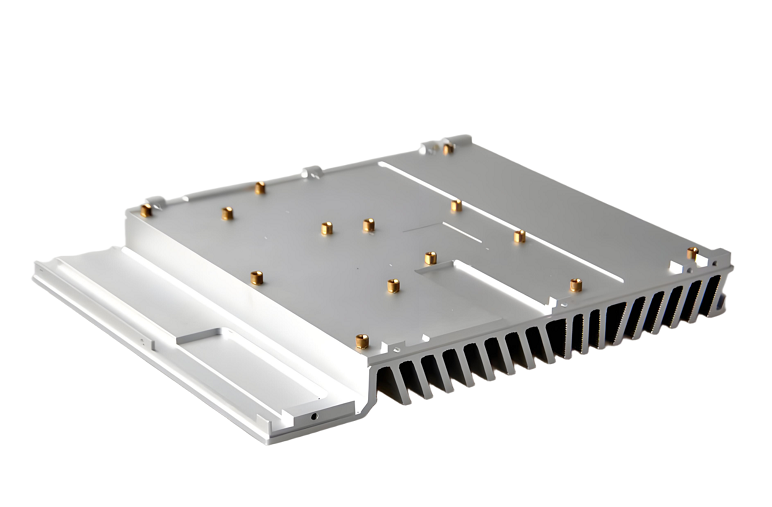

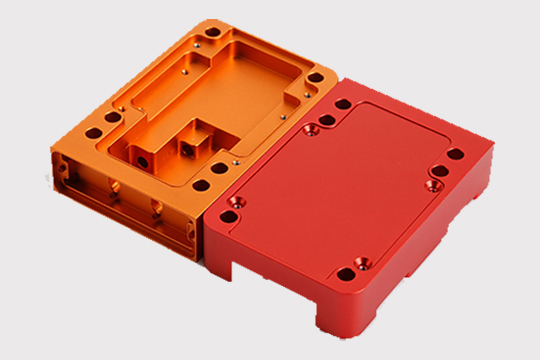

Liquid Cold Plates for Semiconductor Equipment

Kingka’s Liquid Cold Plates — including FSW Liquid Cold Plates, Tube Liquid Cold Plates, Brazed Liquid Cold Plates, and CPU Water Blocks — are designed to efficiently remove heat from high-power semiconductor modules.

Key features include:

Optimized cold plate design for uniform heat distribution

Integration with water cooling circuits for precise temperature control

Support for small cold plates, tube cold plates, and standard cold plates to fit compact equipment layouts

Reliable performance in water cooled electronics systems

These solutions are widely used in wafer processing equipment, chip testers, laser lithography systems, and high-density packaging machines, ensuring stable operation even under continuous high-load conditions.

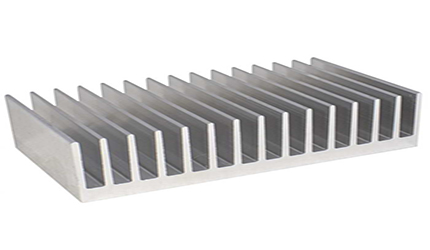

Heat Sinks for Semiconductor Systems

In addition to cold plates, Kingka Heat Sinks provide high-efficiency thermal management for semiconductor applications. Our offerings include aluminum heat sinks, copper heat sinks, extruded heat sinks, finned heat sinks, and liquid cooled heat sinks.

Advantages include:

Enhanced heat sink thermal conductivity and heat sink efficiency

Integration with heat sink with water cooling, heat sink with heat pipe, or liquid cooled heat sink designs

Flexible solutions for high-density electronics, power semiconductors, and laser drivers

Reduced thermal stress to prolong component lifespan

Applications in Semiconductor Manufacturing

Kingka’s Liquid Cold Plates and Heat Sinks are applied in:

Wafer fabrication equipment

Chip assembly and packaging machines

Laser lithography systems

High-performance testing equipment

Power semiconductor modules and converters

By maintaining optimal temperatures, these thermal solutions improve component reliability, yield, and system efficiency, which are critical in semiconductor manufacturing.

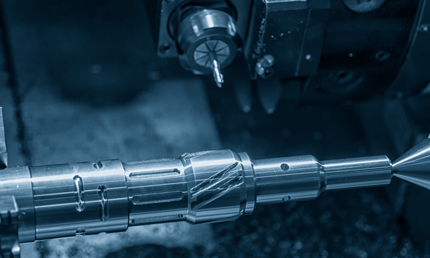

Why Kingka

With extensive expertise in thermal management technology, Kingka delivers tailored Liquid Cold Plates and Heat Sinks that meet the unique needs of the semiconductor industry. Our advanced water cooling technology, cold plate electronics cooling, and heat sink design ensure precise temperature control, high efficiency, and long-term reliability for your semiconductor systems.