With the rapid evolution of the electronics industry, devices are becoming smaller, faster, and more powerful. As component density increases, so does the heat generated by CPUs, GPUs, IGBTs, and other power semiconductors. Effective thermal management has become crucial for ensuring system reliability and long-term performance. Kingka provides comprehensive cooling solutions, including Liquid Cold Plates (water cooled cold plates) and heat sinks, tailored for high-performance electronic applications.

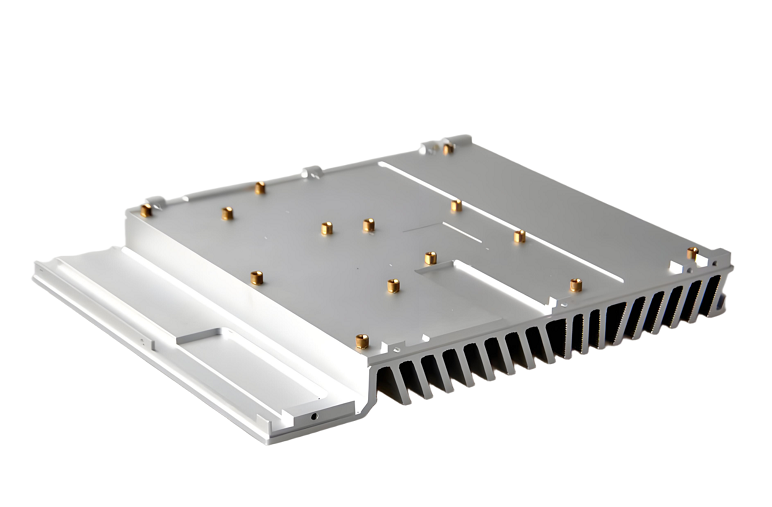

Liquid Cold Plates: Precision Cooling for High-Power Electronics

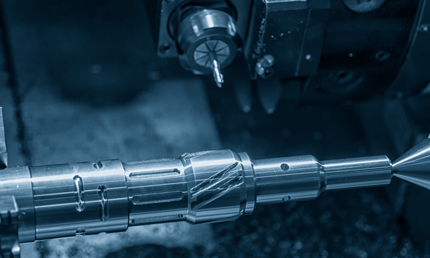

Kingka’s Liquid Cold Plate series — including FSW Liquid Cold Plate, Tube Liquid Cold Plate, and Brazed Liquid Cold Plate — are engineered to manage heat in power electronics, inverters, and control systems. These cooling plates for electronics use advanced water cooling technology and optimized cold plate design to ensure efficient heat transfer away from critical components.

By integrating a water cooling circuit or water cooling system for industry, our liquid cold plate cooling solutions maintain optimal operating temperatures, significantly reducing the risk of overheating and failure. Whether used in data acquisition systems, industrial control modules, or consumer electronics, Kingka’s water cooled cold plates deliver stable and reliable performance.

Features of Kingka Liquid Cold Plates:

High-precision cold plate electronics cooling for sensitive circuits

Efficient water heat sink and heat sink water integration

Custom small cold plate and standard cold plates available

Excellent compatibility with water cooled electronics systems

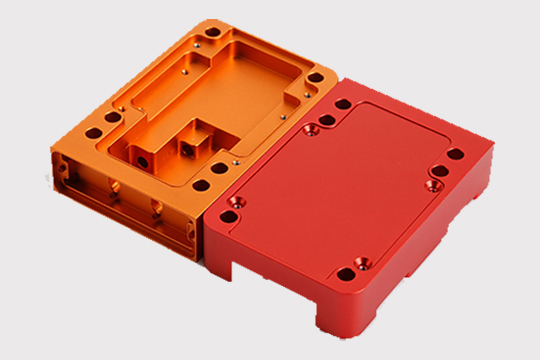

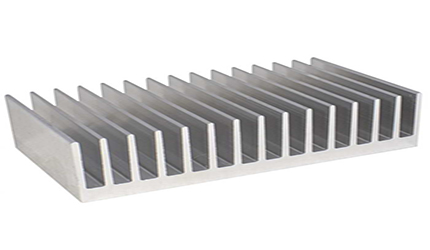

Heat Sinks: Proven Air and Liquid Cooling Efficiency

In addition to cold plates, Kingka manufactures a full range of Heat Sinks for the electronics industry, including aluminum heat sinks, copper heat sinks, extruded heat sinks, and skived fin heat sinks. These thermal solutions are designed for everything from PCB components and LED drivers to power supplies and signal processing units.

Our liquid cooled heat sinks and water cooled heat sinks combine the advantages of air cooling and water cooling plates, enabling flexible design for compact electronics. Kingka also supports heat sink with fan, heat sink with heat pipe, and cold plate heat sink designs for high-power applications such as servers, communication systems, and industrial electronics.

Advantages of Kingka Heat Sinks:

Optimized heat sink design and heat sink fin design for maximum surface area

Wide material range: extruded aluminum heat sink, copper heat sink plate, and liquid heat sink options

Supports heat sink liquid cooling and water cooling technology integration

Enhanced heat sink thermal resistance and heat sink efficiency for performance stability

Applications in Modern Electronics

Kingka’s heat sink solutions and liquid cold plates are widely applied in:

Power converters and motor controllers

Consumer electronics and smart devices

LED lighting drivers and display systems

Industrial automation and semiconductor equipment

These cooling plates and heat sinks ensure that sensitive circuits operate within safe temperature limits, improving electronic component reliability, energy efficiency, and system longevity.

Why Choose Kingka

With advanced heat sink technology, precise cold plate manufacturing, and over 20 years of engineering experience, Kingka offers customized thermal management solutions for global electronics manufacturers. From cold plate design optimization to liquid cooled heat sink assembly, our team ensures every product delivers maximum cooling efficiency and structural stability.

Kingka continues to innovate in water cooling technology, heat sink system integration, and cold plate cooling solutions, empowering the next generation of intelligent electronics with superior thermal control.