Modern vehicles, especially electric vehicles (EVs), hybrid vehicles, and connected smart cars, integrate numerous high-power electronic systems, including battery modules, power inverters, onboard computers, LED lighting systems, and infotainment units. These systems generate significant heat, which can reduce performance, reliability, and safety if not managed effectively. Kingka’s Liquid Cold Plates and heat sinks provide reliable, high-efficiency thermal management solutions tailored for automotive applications.

Liquid Cold Plates for Automotive Applications

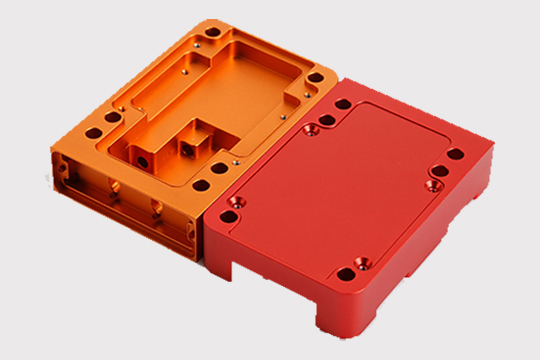

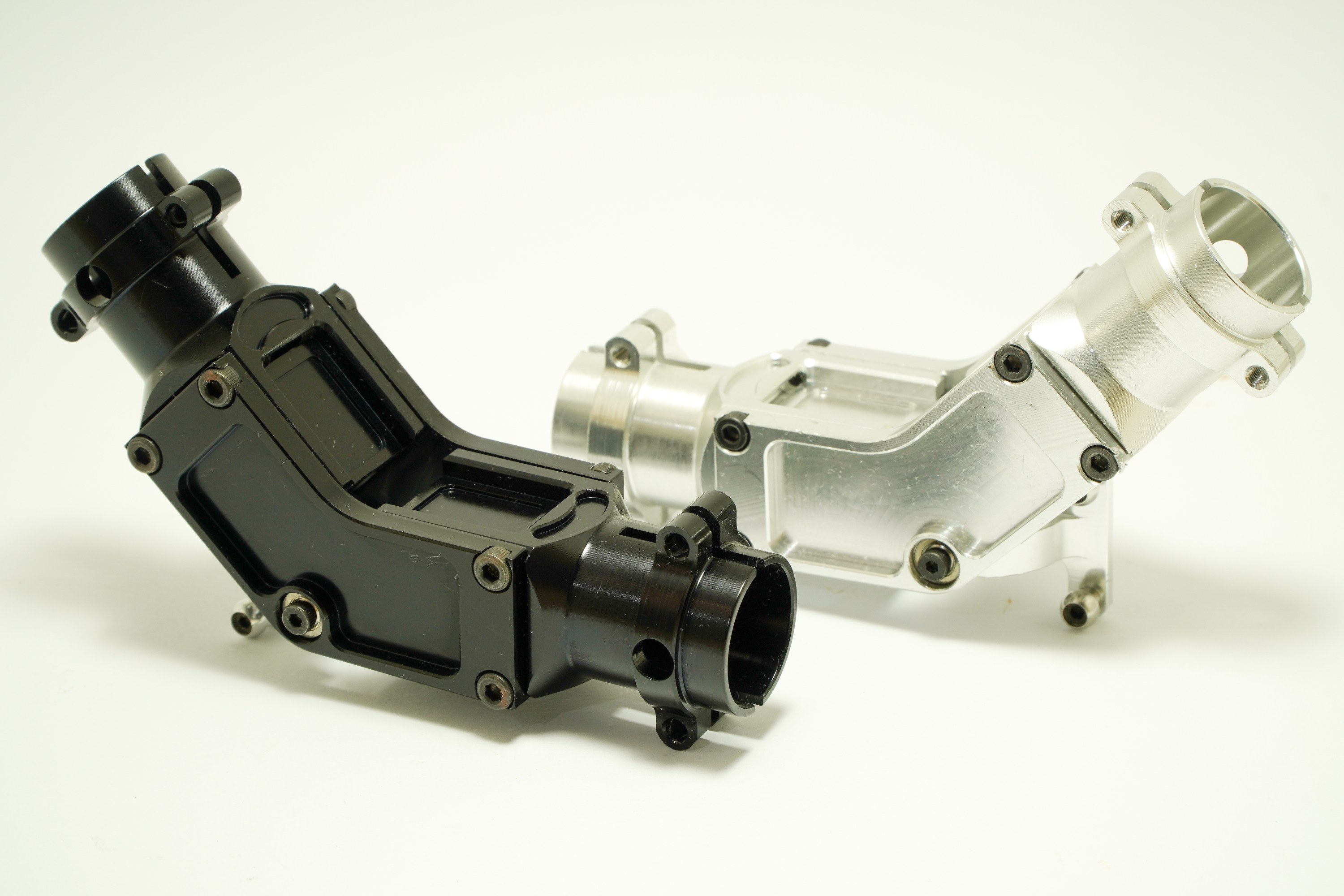

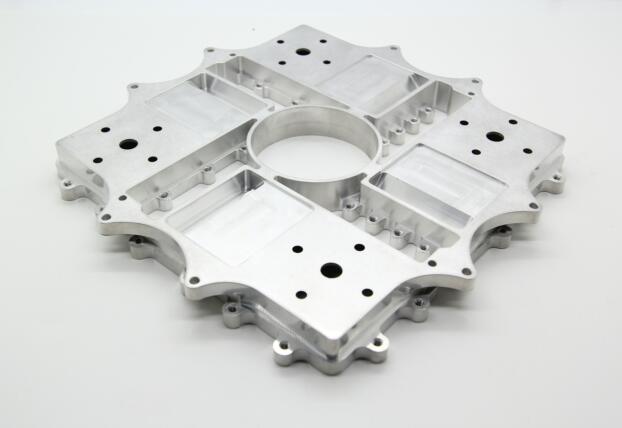

Kingka offers a variety of Liquid Cold Plates, including FSW Liquid Cold Plates, Tube Liquid Cold Plates, and Brazed Liquid Cold Plates, designed to provide precise thermal control for high-density automotive electronics.

Key Advantages:

Optimized Cold Plate Design – Uniformly dissipates heat from battery modules, power electronics, and onboard computing systems.

Integration with Water Cooling Systems – Compatible with water cooling circuits and industrial water cooling systems to ensure precise temperature management.

Custom Solutions – Supports small cold plates, standard cold plates, and tube cold plates, adaptable to compact EV designs or high-power automotive modules.

Enhanced Electronics Cooling – Maintains stable operating temperatures, protecting sensitive components and improving system reliability.

Applications of Liquid Cold Plates in Automotive:

Battery thermal management for EVs and hybrid vehicles

Inverter and power electronics cooling

Onboard computing and ADAS (Advanced Driver Assistance Systems)

High-power LED automotive lighting systems

Heat Sinks for Automotive Systems

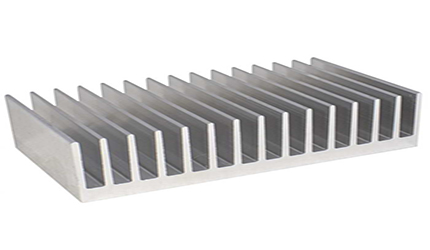

In addition to liquid cooling, Kingka provides a wide range of Heat Sinks, including aluminum heat sinks, copper heat sinks, extruded heat sinks, and water cooled heat sinks, to manage thermal loads in automotive electronics.

Advantages of Kingka Heat Sinks:

Efficient Heat Dissipation – Optimized heat sink design and fin structures effectively remove heat from power electronics and LED systems.

Flexible Integration – Supports heat sink with water cooling or liquid cooled heat sink designs for EVs and high-performance vehicles.

Custom Engineering – Solutions for industrial heat sinks, high-performance automotive heat sinks, and liquid cooled electronics.

Improved Component Reliability – Reduces thermal stress, ensuring consistent performance and longer lifespan for automotive electronics.

Heat Sink Applications in Automotive:

Power inverters and converters

Battery management modules

Electric motor controllers and drives

High-power automotive LED lighting

Benefits for the Automotive Industry

Kingka’s Liquid Cold Plates and Heat Sinks provide key advantages:

Enhanced Battery Performance and Safety – Precise cooling ensures stable temperature for EV battery modules, improving charging efficiency and lifespan.

Reliable Power Electronics – Maintains optimal operating conditions for inverters, motor controllers, and high-power electronic components.

Extended Component Lifespan – Reduces thermal stress on sensitive electronics, enhancing overall vehicle reliability.

Design Flexibility – Supports compact layouts and high-density integration for modern automotive systems.

By offering efficient and precise thermal management, Kingka enables automotive manufacturers to achieve high performance, safety, and reliability in both conventional and electric vehicles.

Why Kingka

With extensive experience in thermal management technology, Kingka delivers custom Liquid Cold Plates and Heat Sinks for automotive applications, ensuring:

Precise thermal control for high-power automotive electronics

Reliable operation under continuous driving conditions

Integration with automotive water cooling systems and circuits

Optimized heat dissipation for compact and high-density electronic modules

Kingka’s thermal solutions help automotive engineers and manufacturers enhance efficiency, safety, and component longevity in next-generation vehicles.