KINGKA Precision Hardware Processing Manufacturer

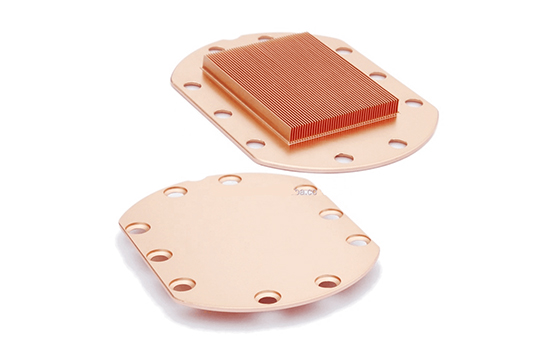

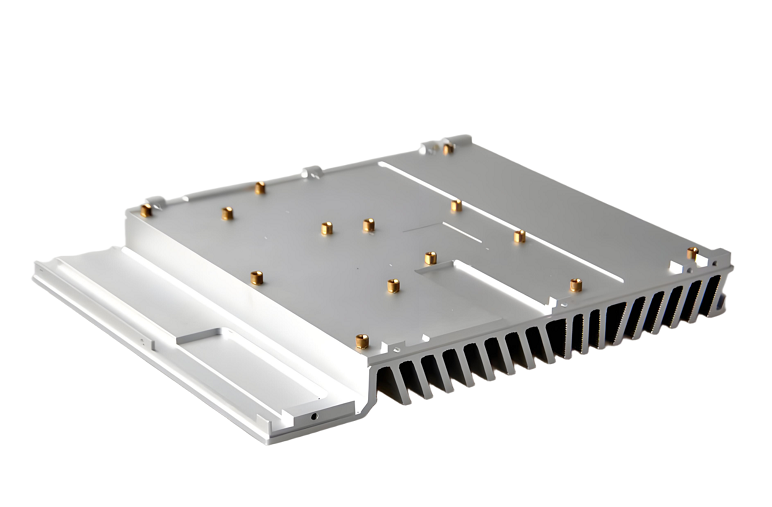

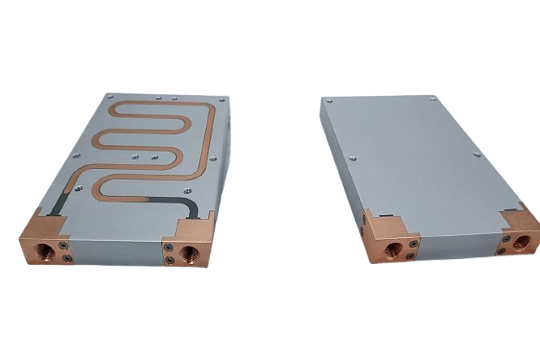

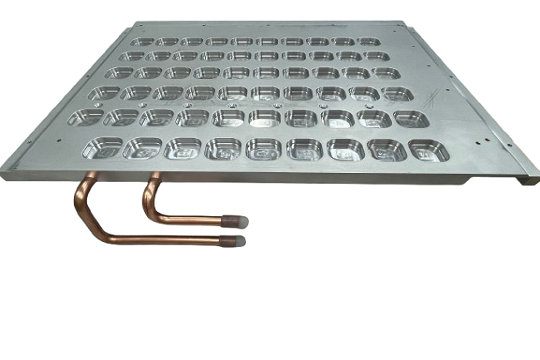

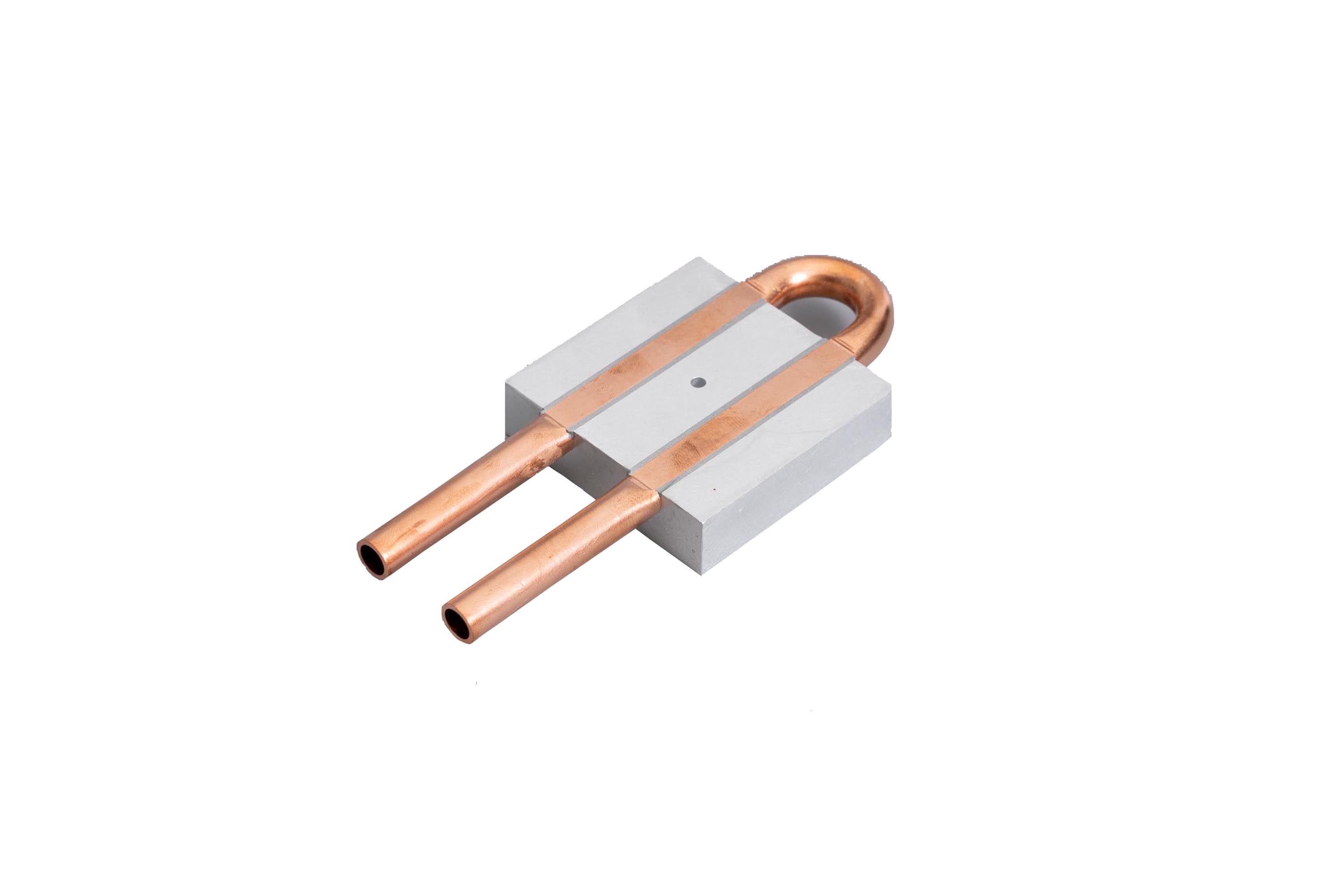

Heat Sink & Water Cooling Plate Customization

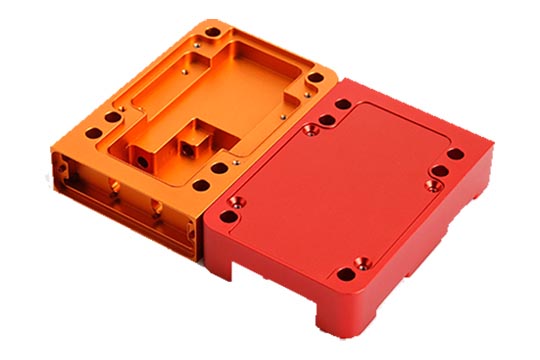

CNC & Sheet Metal One-Stop Service

KINGKA is a trusted manufacturer with 15 years of experience in thermal management solutions and precision machining components. We specialize in high-performance heat sinks, custom liquid cooling plates, and precision machined parts for industries like Data Center, electronics, and renewable energy.

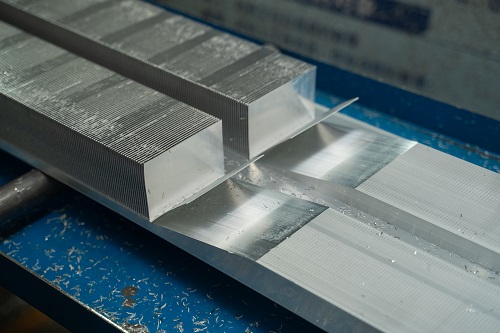

Equipped with over 50+ advanced machines, including CNC, skiving, and friction stir welding systems, our factory ensures top-quality production from prototyping to mass delivery. With rigorous quality control, innovative designs,and a commitment to excellence, KINGKA delivers reliable, cost-effective solutions to clients worldwide.

At KINGKA, we combine cutting-edge technology with skilled craftsmanship to drive innovation and excellence in every product we deliver.

At KINGKA, we deliver end-to-end solutions tailored to your needs:

From concept to completion, KINGKA combines cutting-edge technology, strict quality standards, and efficient logistics to meet your thermal management needs.

KINGKA focuses on the research and development and precision manufacturing of thermal management components such as high-end radiators and water cooling plates, with more than 23 years of industry experience. We are able to provide you with a one-stop service from design to delivery, ensuring that your products meet the highest standards in quality and performance.

The following is our carefully designed manufacturing process, and our expertise and pursuit of quality can be seen at every step:

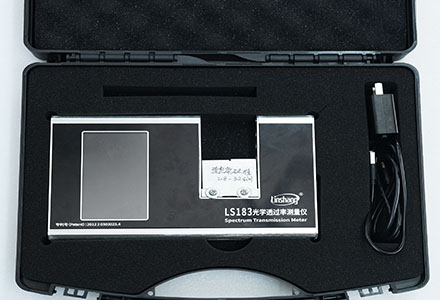

We always put quality first and are equipped with advanced testing equipment to ensurethat every product meets the

highest standards. From precision dimensional measurement to surface treatment testing,

we conduct a full range of quality control to ensure that the performance indicators of the products meet the design requirements. Strict control of every link

enables us to provide customers with more reliable and high-quality products that exceed your expectations.

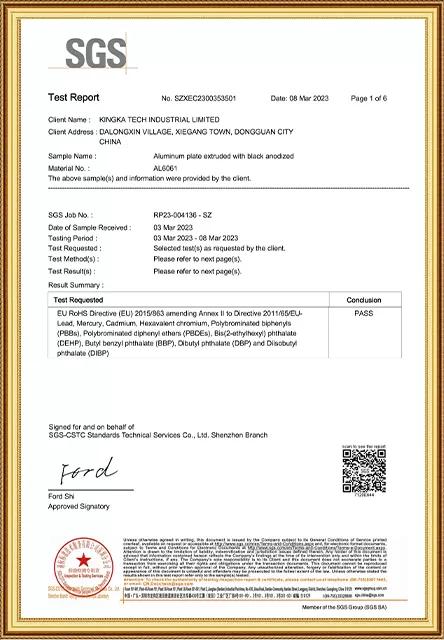

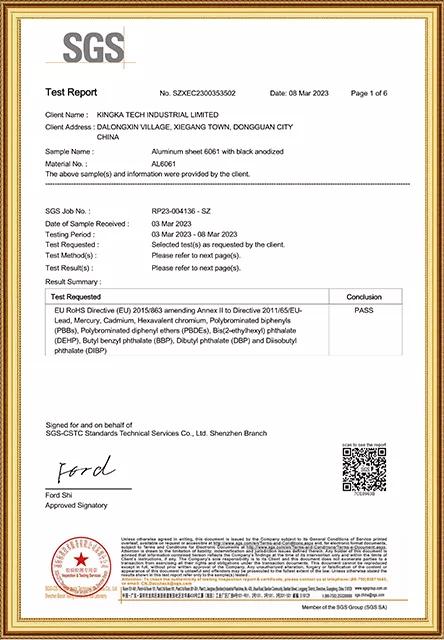

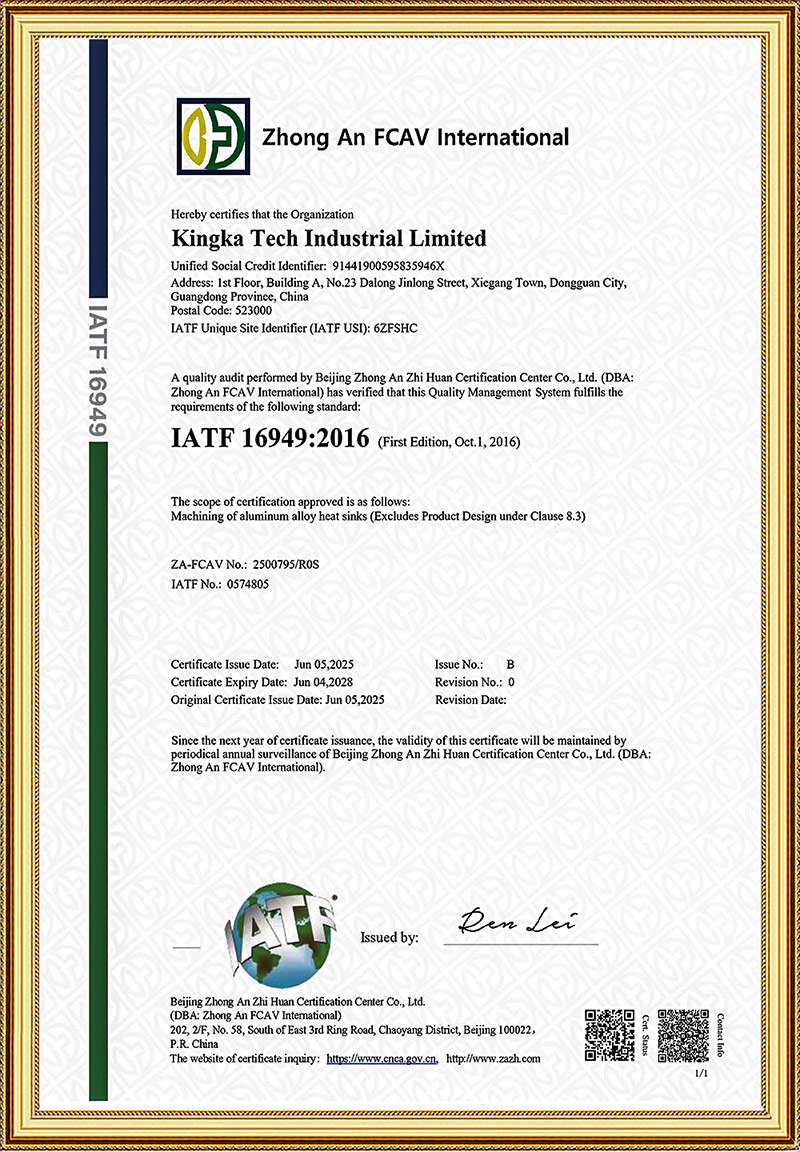

KINGKA can provide customers with excellent product quality, and this commitment is supported by multiple international and domestic certifications. We have test reports issued by SGS to guarantee the high standard quality of our products. In addition, we have obtained the quality management system certification certified by SIRA, which complies with the GB/T19001-2016 idt ISO9001:2015 standard, as well as the IATF16949:2016 certification—further ensuring that our management system and product quality meet international standards.

We appreciate your interest in Kingka. Want to learn more about what we do, have questions or need a quote?

Fill out the form below and we will respond to your inquiry within two business days.

Email:kenny@kingkametal.com

Tel:+86 137 1244 4018

Add: Da Long New Village, Xie Gang Town, DongguanCity, Guangdong Province, China 523598

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018