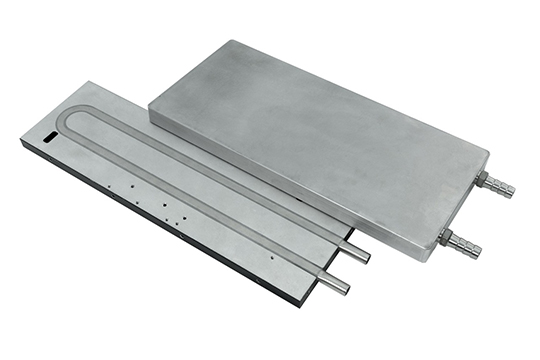

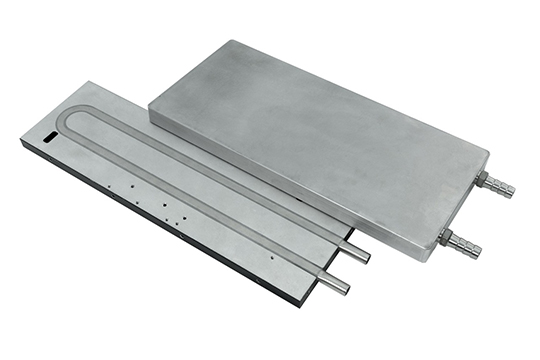

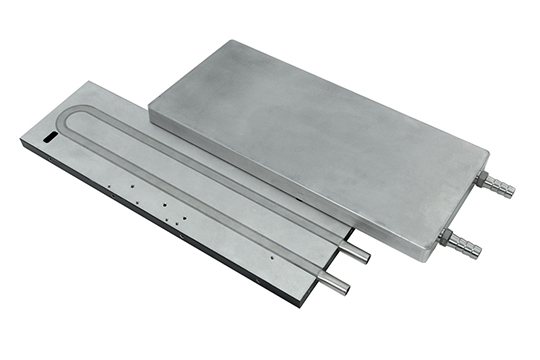

Tube Liquid Cold Plate Parts are essential components in high-performance liquid cooling systems, engineered to deliver efficient heat dissipation for thermally demanding applications. These parts consist of metal plates with embedded or brazed tubing that channels liquid coolant directly beneath heat-generating components. Designed for modular integration, they offer flexible design and superior cooling efficiency, making them ideal for industrial electronics, medical devices, EV systems, and renewable energy equipment.

We utilize advanced machinery to ensure precision and high reliability:

CNC Machining Centers for structural shaping

Tube Bending Machines for custom coolant paths

Automatic Brazing Equipment for tube-to-plate bonding

Leak Detection Systems (Helium/Pressure)

Ultrasonic Cleaning Machines for contaminant removal

These machines support both standard and customized production for tube-based liquid cold plate modules.

Our Tube Liquid Cold Plate Parts are produced using a combination of:

Brazing – for secure bonding of copper, stainless steel, or aluminum tubing to base plates

CNC Milling – to create precision mounting surfaces and component pockets

Tube Flattening and Insertion – for optimal contact with heat sources

Leak and Pressure Testing – to ensure long-term reliability and safety

We support a wide range of materials to match different thermal and mechanical needs:

Aluminum Base Plates (6061/5052) – lightweight and cost-effective

Copper Tubes (C110/C122) – high thermal conductivity

Stainless Steel Tubes (304/316) – corrosion resistance for aggressive environments

Precision Tolerance:

Flatness: ≤ 0.1 mm

Hole Positioning: ±0.05 mm

Tube Wall Thickness: ±0.1 mm

To enhance corrosion resistance, durability, and surface quality, we offer:

Anodizing (for aluminum plates)

Nickel or Tin Plating (for copper/stainless steel tubes)

Powder Coating or Custom Surface Finishes for aesthetic or functional needs

Tube Liquid Cold Plate Parts are widely used in:

Electric Vehicle Battery Packs and Inverters

Industrial Laser Cooling Systems

Medical Imaging Equipment (MRI/CT)

Data Center Servers & Telecom Power Units

Wind and Solar Energy Converters

Automation and Robotics Control Modules

Flexible Design: Easy to customize tubing paths, plate size, and mounting options

High Thermal Efficiency: Tubes positioned directly under heat sources for rapid heat transfer

Modular Construction: Compatible with existing heat sink and chassis systems

Durable and Leak-Proof: Pressure-tested and brazed for long-term operation

Material Versatility: Supports hybrid metal combinations for targeted applications

OEM/ODM Support: Ideal for custom cooling system developers and integrators

Q1: What’s the difference between a tube cold plate and a FSW cold plate?

A: Tube cold plates use embedded or bonded tubing for coolant flow, offering flexible design and lower cost. FSW cold plates integrate fluid channels directly into the plate via friction stir welding, offering higher strength and uniform heat transfer.

Q2: Can I customize the tube layout and port configuration?

A: Yes, we support full customization, including U-bend, serpentine, or spiral paths, and custom inlet/outlet fittings based on your assembly and flow requirements.

Q3: What is the maximum operating pressure and temperature?

A: Typically, up to 5–8 bar pressure and temperatures ranging from -40°C to 120°C, depending on the materials and brazing method used.

Q4: What coolants are supported?

A: Water, deionized water, glycol-water mixtures, dielectric fluids. Material compatibility with the coolant is ensured during design.

Q5: What quality assurance measures do you take?

A: 100% leak and pressure testing, dimensional inspection, surface flatness check, and material traceability for each batch.

Q6: Do you offer rapid prototyping?

A: Yes. We offer low-volume prototyping and quick-turn custom samples with full technical support.

Q7: What is the lead time for custom tube cold plates?

A: Standard parts ship in 2–3 weeks. Custom cold plates require 4–5 weeks depending on complexity and quantity.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018