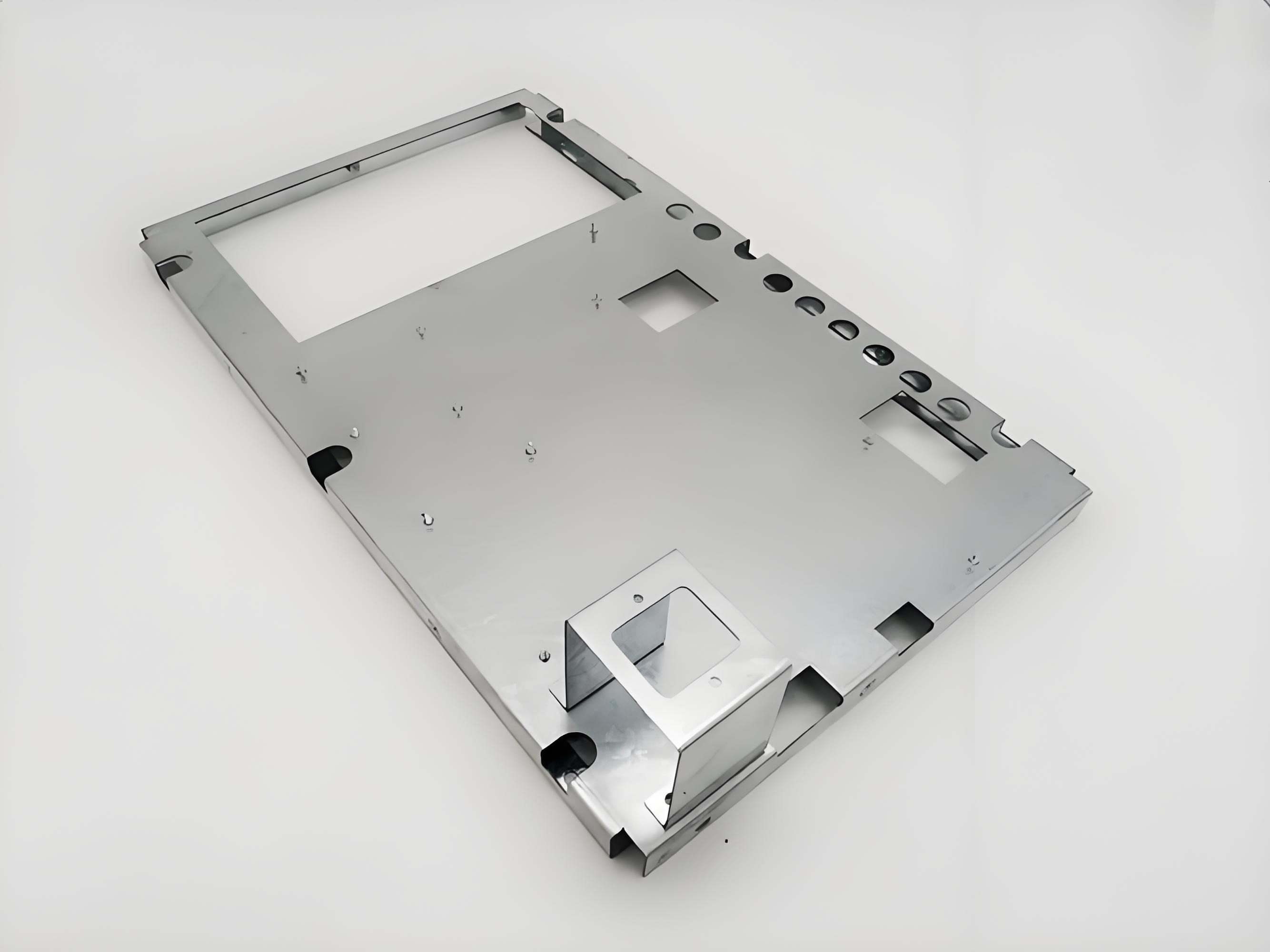

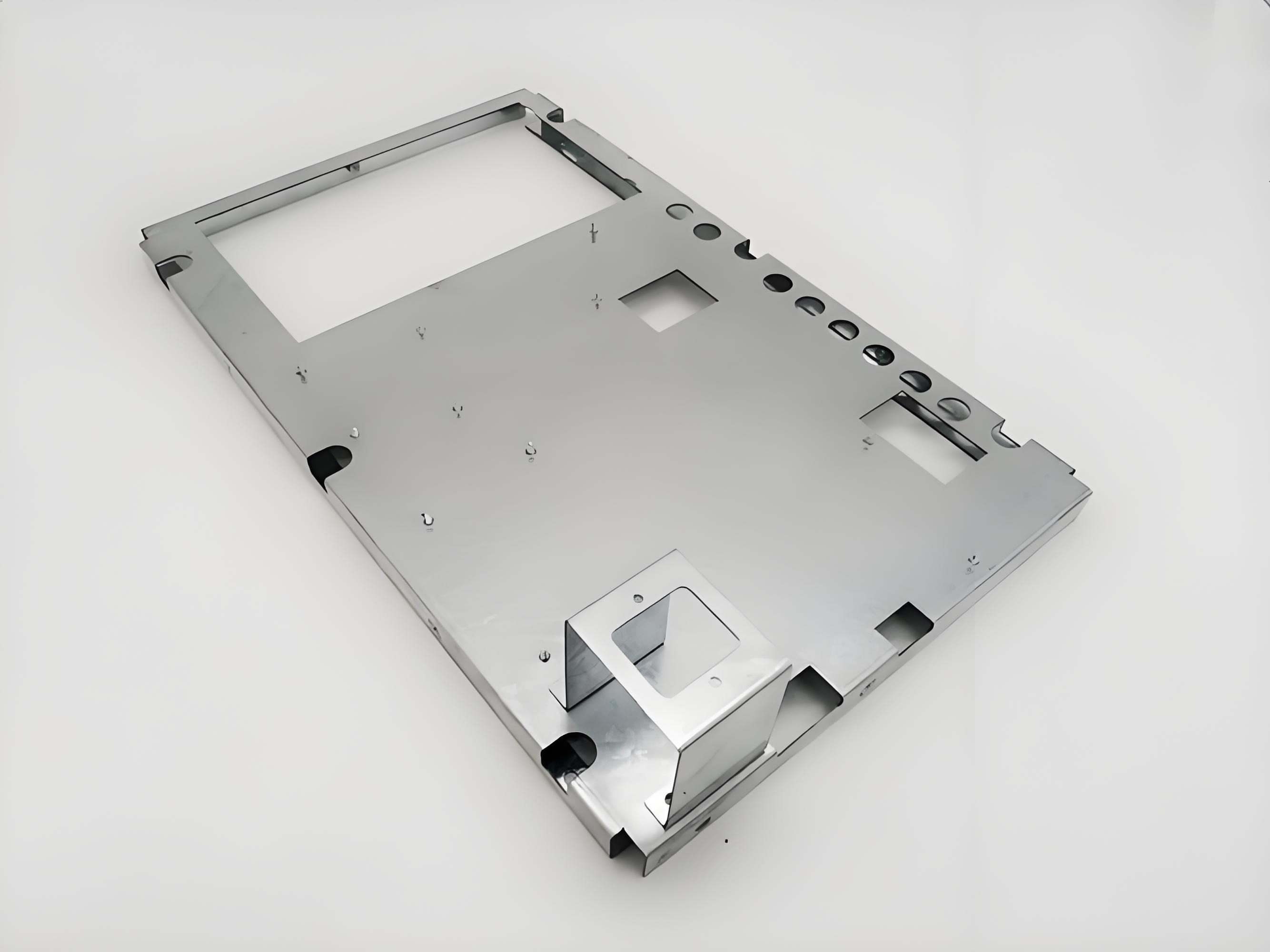

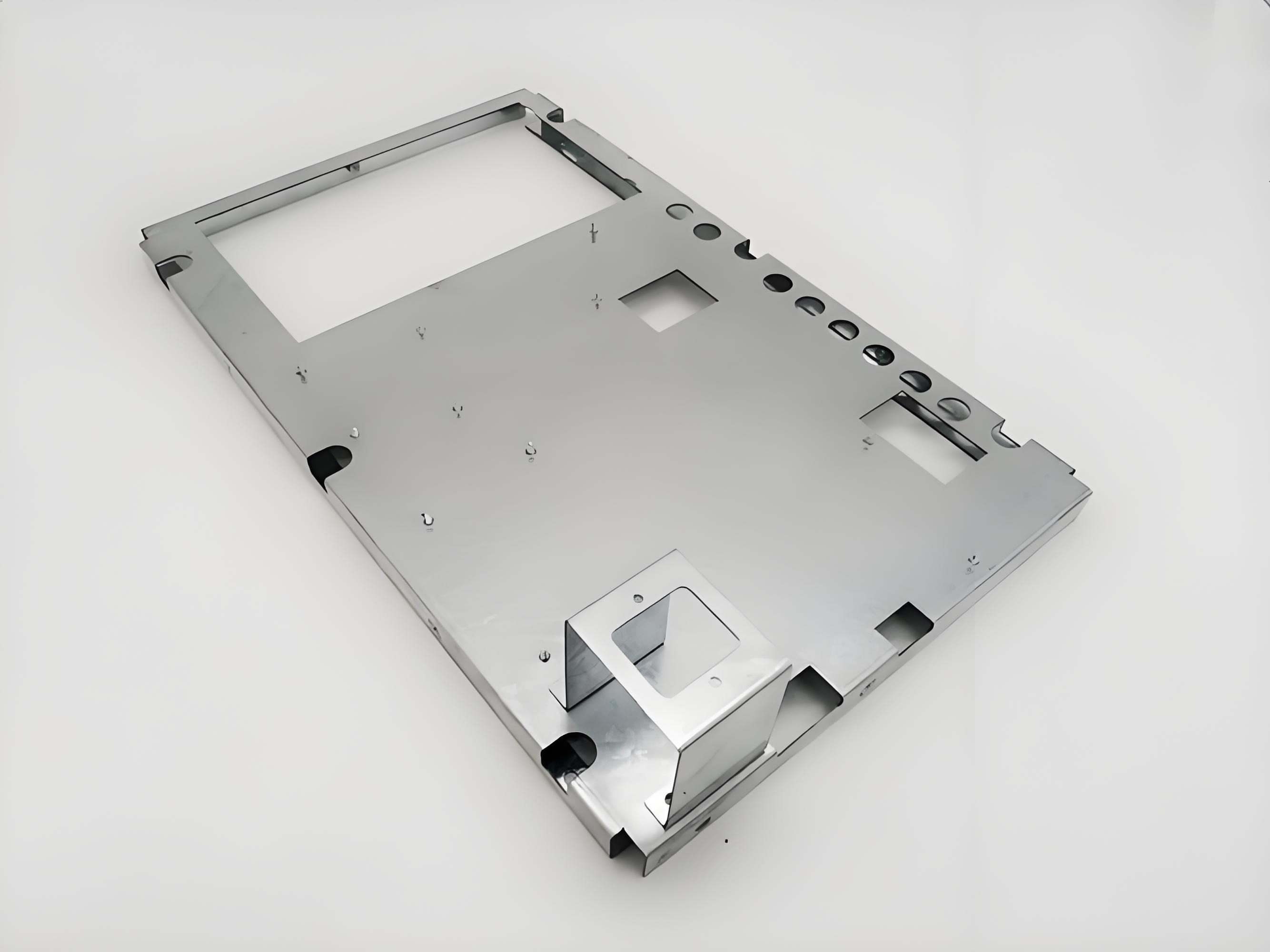

At KINGKA, we specialize in Custom Sheet Metal Assemblies and precision Sheet Metal Fabrication solutions designed to meet the demanding needs of diverse industries — from automotive and electronics to renewable energy and telecommunications. With over 15 years of engineering and manufacturing experience, KINGKA stands as a trusted partner for precision sheet metal assemblies and complex component fabrication.

Our sheet metal assembly services cover the full spectrum from prototyping to mass production. Utilizing advanced CNC machining, laser cutting, and high-precision forming technologies, KINGKA delivers reliable, high-quality sheet metal assemblies with tight tolerances (±0.01mm) and superior structural integrity.

Custom Sheet Metal Assemblies: Tailored designs to fit your unique application requirements.

Precision Sheet Metal Assemblies: Achieving ultra-tight tolerances for optimal performance.

Welded, Riveted, and Bolted Assemblies: Employing diverse joining techniques to suit structural and functional demands.

CNC Sheet Metal Assemblies: Utilizing 5-axis CNC machines for intricate and complex geometries.

High-Volume Sheet Metal Fabrication: Progressive die stamping and automated forming ensure cost-effective production scalability.

KINGKA is equipped with 38+ cutting-edge machines, including state-of-the-art CNC centers, laser cutting systems, and precision forming presses. This enables us to produce complex sheet metal parts assemblies with high consistency and efficiency, whether it’s a small batch prototype or large-scale industrial orders.

We are ISO 9001:2015 certified and IATF 16949 compliant, underscoring our commitment to quality, especially for automotive and high-reliability sectors. Every sheet metal assembly undergoes strict dimensional inspections with 3D optical projection and CMM technology, ensuring your products meet exacting specifications.

Our engineering team provides comprehensive sheet metal assembly design and DFM (Design for Manufacturability) services. Leveraging advanced CAD and thermal simulation tools, we optimize your product design for cost-effectiveness, durability, and performance.

Applications of Our Sheet Metal Assemblies

Applications of Our Sheet Metal AssembliesKINGKA’s sheet metal assemblies are integral components in various industries, including but not limited to:

Automotive Sheet Metal Assemblies: Frames, brackets, housings for electric vehicles and conventional cars.

Electronics and Telecommunications: Enclosures, chassis, and mounting hardware.

Renewable Energy: Structural assemblies for solar panels and energy storage systems.

Medical Devices: Precision components requiring stringent quality standards.

Partner with KINGKA to access premium sheet metal assembly fabrication services that combine innovation, precision, and reliability. Our flexible manufacturing lines and expert craftsmanship empower you to bring complex designs to life with confidence and on schedule.

1. What are Sheet Metal Assemblies?

Sheet Metal Assemblies are complete units made by joining multiple sheet metal parts through welding, riveting, bolting, or other fastening methods. They are widely used across industries such as automotive, electronics, telecommunications, and medical devices.

2. What Sheet Metal Assembly services does KINGKA provide?

KINGKA offers full-service solutions from design and prototyping to mass production, including precision CNC machining, laser cutting, bending, and progressive die stamping.

3. What is the machining precision of KINGKA’s Sheet Metal Assemblies?

Our sheet metal assemblies are manufactured with ultra-tight tolerances up to ±0.01mm, using advanced 5-axis CNC machines and comprehensive inspection systems to ensure the highest quality.

4. What materials do you work with for sheet metal fabrication?

We work with a wide range of materials including aluminum alloys, stainless steel, carbon steel, copper, and specialty alloys to meet diverse application needs.

5. How does KINGKA ensure product quality?

KINGKA is ISO 9001:2015 certified and follows rigorous quality control protocols including 3D optical inspection, CMM measurement, and detailed testing to ensure all products meet exact specifications.

6. What is the minimum order quantity (MOQ)?

We accommodate flexible order sizes, from small prototype batches to large-scale mass production, tailored to customer requirements.

7. Do you offer design and engineering support?

Yes, our experienced engineering team provides design-for-manufacturability (DFM), 3D modeling, and thermal simulation to optimize your sheet metal assembly design for performance and cost.

8. What is the typical lead time for production?

Sample production usually takes 2-4 weeks depending on complexity, while mass production lead times are customized based on order volume and design specifics to ensure on-time delivery.

9. Do you support OEM and ODM services?

Absolutely. KINGKA offers OEM and ODM solutions to deliver fully customized sheet metal assemblies tailored to your exact needs.

10. Which industries commonly use KINGKA’s Sheet Metal Assemblies?

Our assemblies serve a variety of industries including automotive, power electronics, telecommunications, medical equipment, and renewable energy sectors.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018