Sheet Metal Fabrication is a core manufacturing process used to produce durable and precise metal components by cutting, bending, punching, welding, and assembling sheet materials. It plays a vital role across industries such as automotive, aerospace, electronics, medical equipment, industrial machinery, and construction.

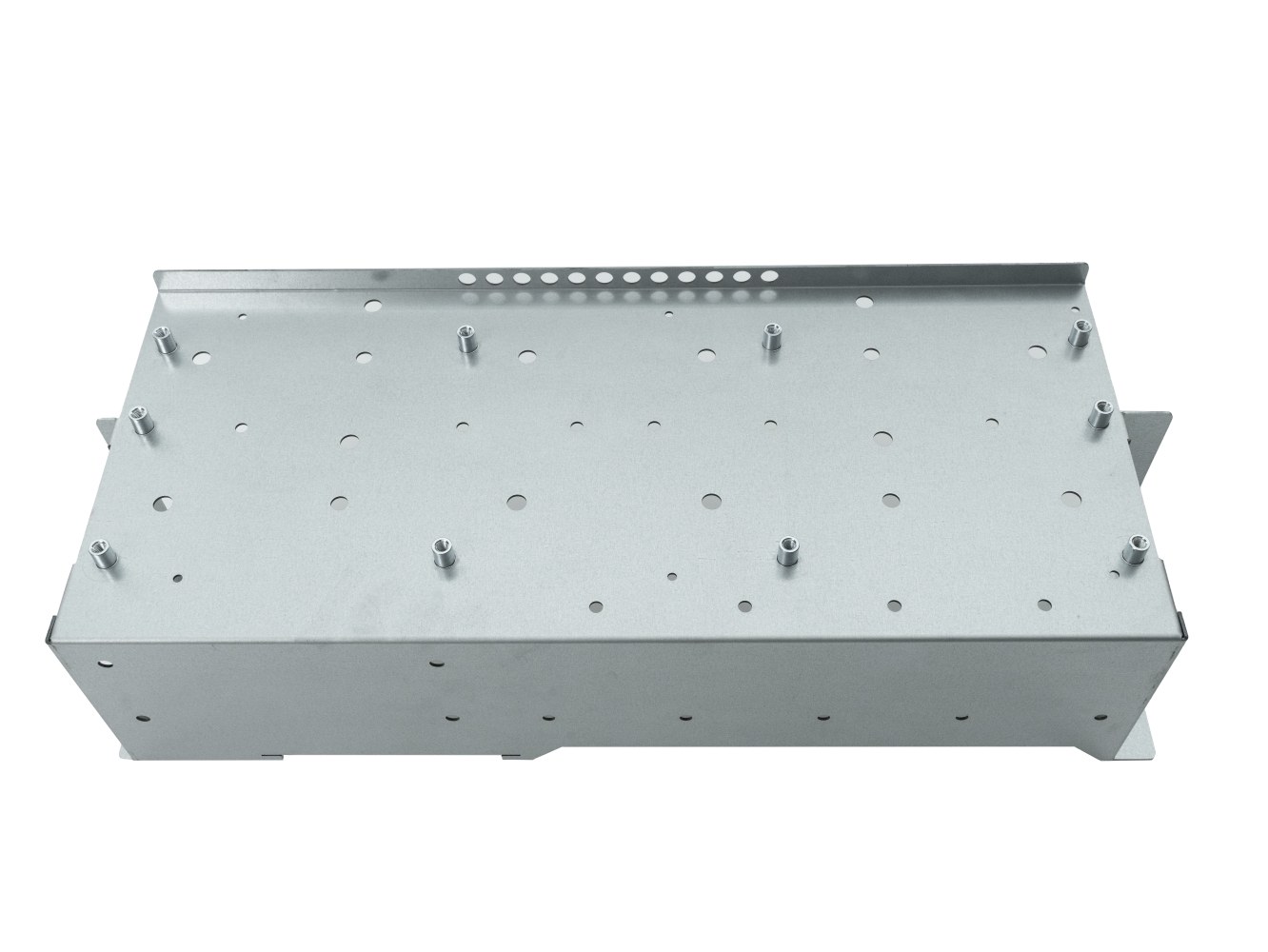

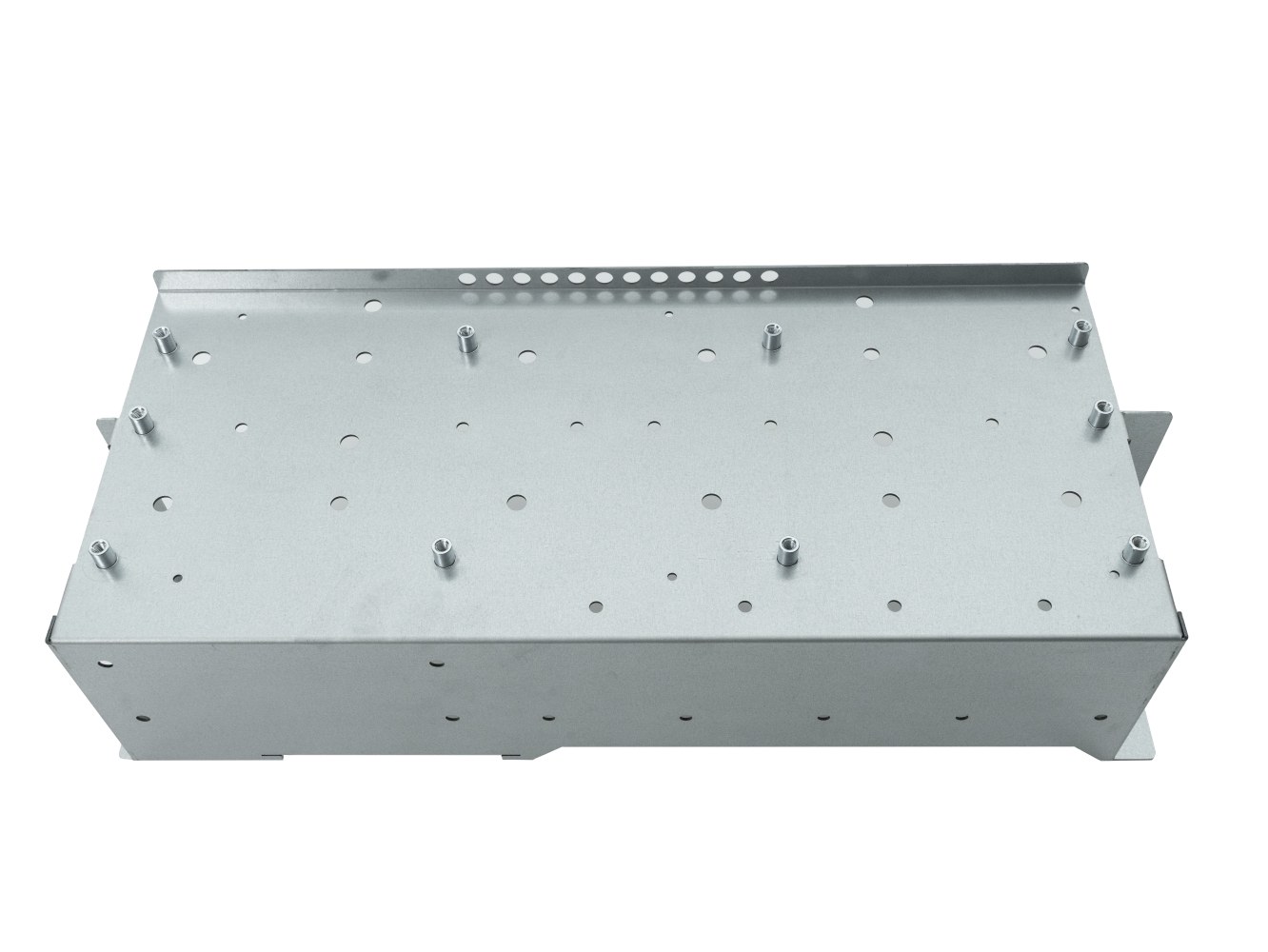

We offer custom Sheet Metal Fabrication services with tight tolerances, fast turnaround, and support for low-volume prototypes to high-volume production runs. Whether you need brackets, enclosures, chassis, cabinets, or custom OEM components, we provide one-stop solutions from design to finished parts.

We integrate multiple sheet metal manufacturing methods to meet complex product needs:

Laser cutting / CNC punching

Bending (Press Brake)

Stamping / Deep Drawing

MIG/TIG/Spot Welding

Riveting / Tapping / Assembly

Surface finishing & powder coating

We work with a broad range of sheet metals:

Cold Rolled Steel (CRS)

Stainless Steel (SS304, SS316)

Aluminum (5052, 6061, 1100)

Galvanized Steel (GI)

Copper / Brass / Titanium

All materials are available in various thicknesses, and we offer RoHS-compliant, UL-listed, and ISO-certified sourcing upon request.

Flatness, hole spacing, and bend angle accuracy controlled within ±0.1mm

Custom tolerances available upon drawing confirmation

| Parameter | Details |

|---|---|

| Thickness Range | 0.2mm – 6mm (depending on material) |

| Max Sheet Size | Up to 1500mm × 3000mm |

| Tolerance | ±0.1mm (cutting & forming) |

| Drawing Formats | DWG, DXF, STEP, IGES, PDF |

| Finishing Options | Powder coating, anodizing, brushing, plating, sandblasting, silk screen printing |

| Batch Size | Prototype to mass production (1–100,000+ pcs) |

| Lead Time | 3–15 working days (depending on complexity) |

Custom Sheet Metal Applications

Electrical Enclosures & Control Boxes

Server Racks & Cabinets

Automotive Panels & Brackets

Medical Equipment Housings

Industrial Machine Covers & Parts

Consumer Product Shells

Chassis for Electronics & Devices

10+ Years of Fabrication Experience

Advanced Equipment – CNC laser cutters, press brakes, welding stations

Skilled Engineers & Technicians

Rapid Prototyping & DFM Support

Certified Quality Control – ISO9001, RoHS, material test reports available

Custom Surface Treatments & Logo Marking

Global Delivery & OEM Service

Standard Packaging: PE bags + foam + export cartons or wooden boxes

Shipping Options: Express (DHL/FedEx), air freight, sea freight (FOB, DDP, EXW available)

Delivery: Global shipping available within 3–15 days

A: Sheet metal fabrication is the process of transforming flat metal sheets into specific shapes and components through cutting, bending, punching, welding, and assembly. It is commonly used in industries like electronics, automotive, medical, and industrial machinery.

A: We work with a wide range of materials including stainless steel, aluminum, cold rolled steel, galvanized steel, copper, and brass. Material thickness ranges from 0.2mm to 6mm.

A: Yes, we specialize in custom sheet metal fabrication services, providing OEM/ODM support, custom dimensions, hole patterns, surface finishes, and logos.

A: Prototype orders can be completed in 3–7 working days. Mass production typically takes 10–20 days depending on complexity and quantity.

A: Absolutely. We support flexible order quantities—from 1 piece prototype to large-scale production with 100,000+ units.

A: We offer powder coating, anodizing, brushing, sandblasting, electroplating, silk screen printing, and more to enhance appearance and corrosion resistance.

A: We accept CAD files in DXF, DWG, STEP, IGES, and PDF formats. If you only have a sample or sketch, we can help you reverse engineer it.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018