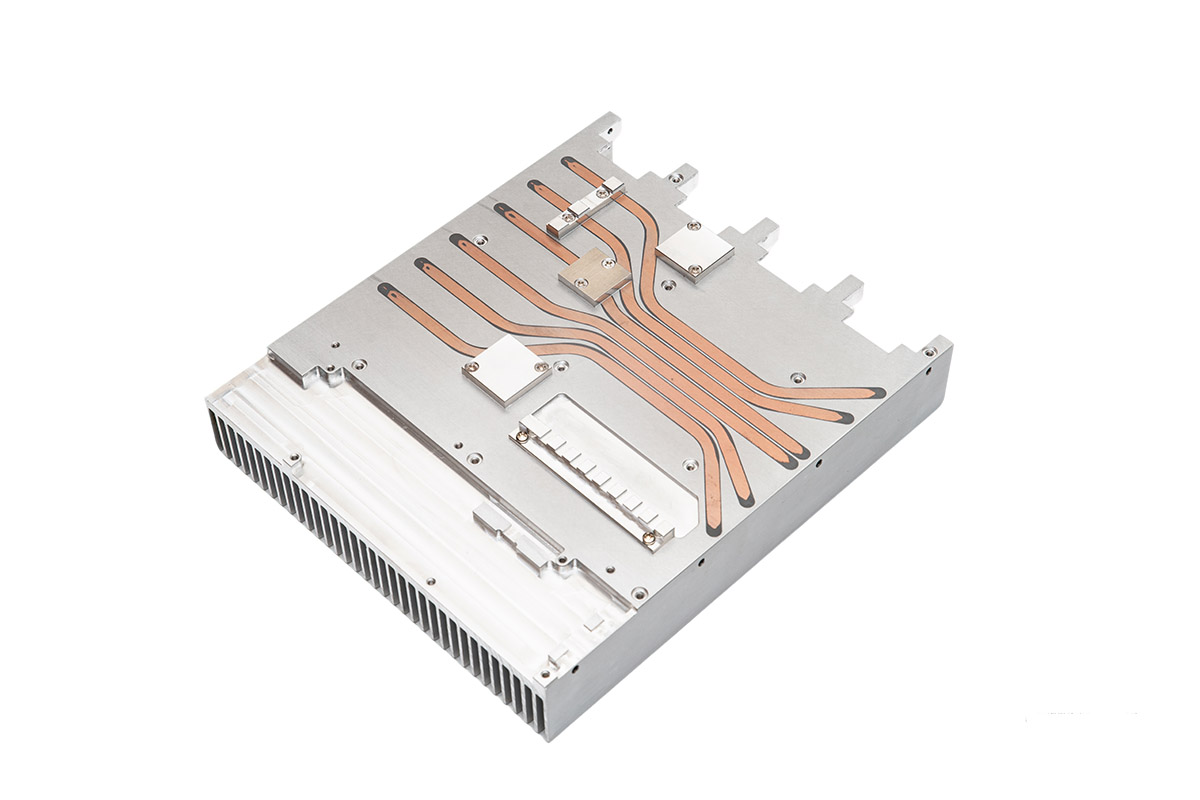

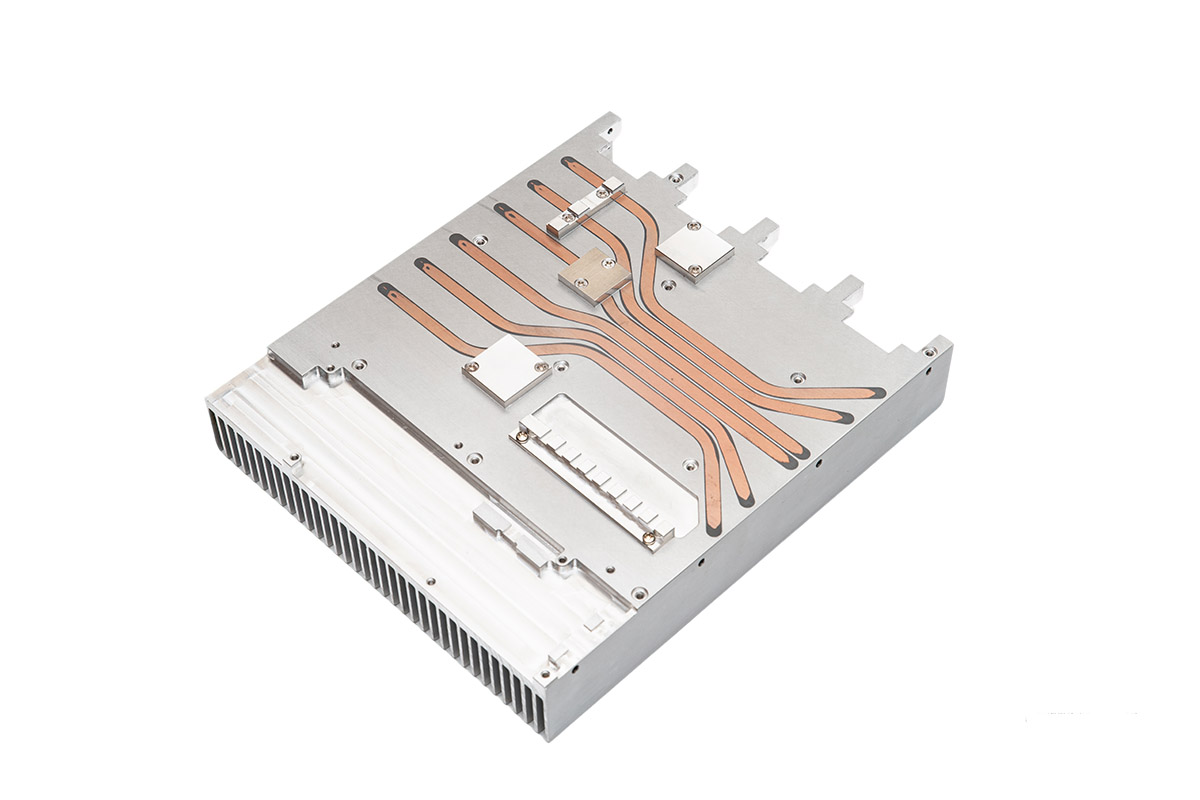

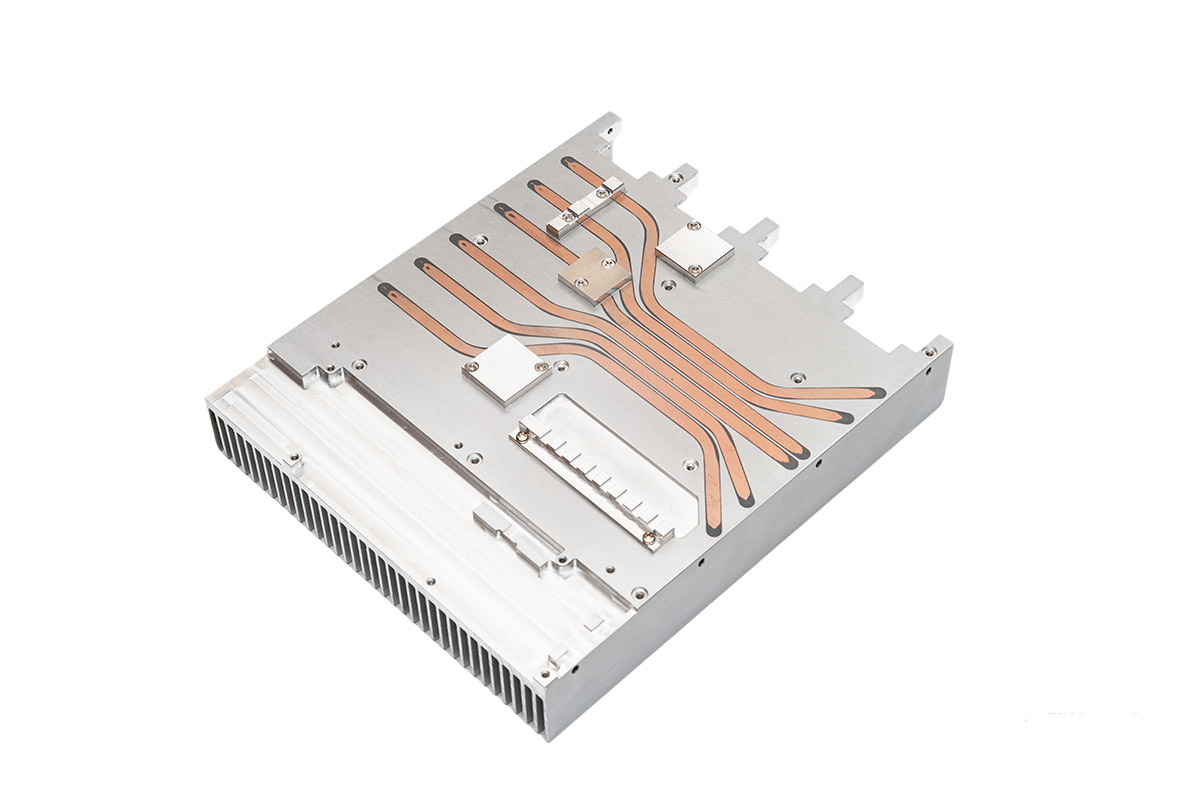

Our Copper Pipe heat sink is a cutting-edge thermal management solution designed for efficient and reliable heat dissipation across a wide range of electronic devices. As a leading OEM Heat Sink manufacturer, we provide premium heat pipe Heat Sinks that combine high thermal conductivity copper pipes with optimized aluminum fins, delivering superior cooling performance for CPUs, GPUs, LEDs, and industrial electronics.

The copper heat pipe heatsink uses multiple copper pipes embedded in a solid copper base. Heat generated by the electronic component is rapidly absorbed by the pipes and transferred to aluminum fins. The fins then dissipate heat into the surrounding air, maintaining safe and stable operating temperatures. This design minimizes thermal resistance and ensures high efficiency, making it one of the best heat pipe heat sinks available in the market.

Key features include:

High Thermal Conductivity: Copper pipes efficiently transfer heat from the source to the fins.

Optimized Aluminum Fins: Enhance surface area for rapid and uniform heat dissipation.

Multi-Heat Pipe Configuration: Supports multiple heat pipes for high-power applications.

Low Noise Operation: Compatible with both passive and fan-assisted cooling systems.

Durable Construction: Premium copper and aluminum ensure long-term performance and corrosion resistance.

Our heat sink with heat pipe solutions are widely used across multiple industries:

CPU Cooling: Ensures stable performance for desktop and server processors.

GPU Cooling: Provides effective thermal management for gaming and high-performance graphics cards.

LED Lighting Systems: High-power LEDs generate significant heat; copper pipe heat sinks extend lifespan and maintain brightness.

Industrial Electronics: Power converters, inverters, and other electronics benefit from efficient cooling.

Telecom Equipment and Data Centers: Maintain optimal performance and reliability.

Custom Heat Pipe Heat Sink Solutions: Tailored designs for unique thermal requirements.

The heat pipe cooler operates on the heat pipe principle: a small amount of working fluid inside a sealed copper pipe vaporizes when heated, rises to the cooler fins, and condenses, releasing heat. The liquid returns to the base via capillary action, creating a continuous thermal transfer cycle. This mechanism allows high-performance heat sinks to remove heat quickly, outperforming traditional solid aluminum heat sinks.

We provide a range of customization options for custom heat pipe heat sinks:

Number of Heat Pipes: From 1 to 6 or more, depending on thermal requirements.

Pipe Diameter: Options include 6mm, 8mm, 10mm, and custom sizes.

Fin Design and Material: Adjustable fin density, thickness, and material selection for optimized airflow.

Shape and Size: Tailored to fit unique device layouts or OEM specifications.

Surface Treatment: Optional nickel plating or anodization for durability and aesthetics.

This flexibility ensures a perfect heat pipe cooling solution for any application, reducing overheating risks and improving device reliability.

Compared to conventional heat sinks, our copper pipe heat sink offers:

Faster Heat Transfer: Copper provides superior thermal conductivity.

Higher Heat Dissipation Efficiency: Multi-pipe design and optimized fins maximize cooling.

Extended Component Lifespan: Efficient cooling reduces thermal stress.

Compatibility with Active and Passive Cooling: Works seamlessly with fans or passive convection.

Reliable and Durable: High-quality materials ensure long-term performance.

By choosing our copper heat pipe heatsink, customers gain:

Stable Device Operation: Maintains safe operating temperatures for electronics.

Energy Efficiency: Reduced need for additional cooling fans.

Cost Savings: Prolongs component life and minimizes maintenance costs.

Custom Solutions: Tailored pipe heat sinks for specific requirements.

Enhanced Product Reliability: High-quality thermal heat sinks reflect positively on OEMs.

Our Copper Pipe Heat Sink is a versatile and reliable solution for all high-performance cooling needs. Whether you need a heat sink for pipe, heat pipe cooler, or a custom heat pipe heat sink, our products provide efficient thermal management, long-lasting durability, and flexible design options. As an experienced OEM heat sink manufacturer, we deliver high-performance heat sinks that meet demanding thermal requirements, keeping your devices safe, efficient, and quiet.

Q1: What is a copper pipe heat sink?

A copper pipe heat sink is a type of heat sink with heat pipe that uses high thermal conductivity copper pipes embedded in a base to efficiently transfer heat from electronic components to aluminum fins. This heat pipe cooler provides fast, reliable, and uniform heat dissipation for CPUs, GPUs, LEDs, and industrial electronics.

Q2: How does a heat pipe heat sink work?

The heat pipe heat sink operates on a phase-change principle. A small amount of working fluid inside the copper pipe vaporizes when heated, moves to the cooler fin area, and condenses, releasing heat. The liquid then returns to the base through capillary action, creating a continuous cycle of heat transfer. This mechanism allows a high performance heat sink to remove heat efficiently and maintain device stability.

Q3: What applications can a copper heat pipe heatsink be used for?

Our copper pipe heat sink is ideal for:

CPU and GPU cooling in computers and servers

High-power LED lighting systems

Industrial electronics and power equipment

Telecom and data center equipment

Any device requiring a heat pipe cooling solution for efficient thermal management

Q4: Can I customize a copper pipe heat sink?

Yes. We offer custom heat pipe heat sinks with:

Adjustable number of heat pipes (1–6 or more)

Custom pipe diameters (6mm, 8mm, 10mm, or others)

Fin density, thickness, and material customization

Shape and size modifications to fit unique device layouts

Surface treatment options (nickel plating or anodization)

Q5: What are the advantages of copper pipe heat sinks over regular aluminum heat sinks?

Compared to traditional aluminum heat sinks, copper heat pipe heatsinks provide:

Faster heat transfer due to superior copper conductivity

Higher heat dissipation efficiency with multi-pipe design

Extended component lifespan due to reduced thermal stress

Compatibility with both passive and fan-assisted cooling systems

Durable performance in industrial or harsh environments

Q6: Are copper pipe heat sinks noisy during operation?

No. When used passively, they operate silently. Even when combined with fans, the heat pipe cooler system is designed to minimize noise while maximizing heat dissipation.

Q7: How do I choose the right heat pipe heat sink for my application?

Consider the following factors:

Power output and heat generated by your component

Available space and airflow conditions

Thermal resistance requirements

Customization needs, including pipe number, diameter, and fin design

Our team can provide guidance and a custom heat pipe heat sink solution tailored to your specific needs.

Q8: Can copper pipe heat sinks be used in LED lighting applications?

Yes. Copper heat pipe heatsinks are widely used in high-power LED systems to prevent overheating, maintain brightness, and extend LED lifespan.

Q9: Are these heat sinks durable?

Absolutely. Made from premium copper and aluminum, our heat sink with heat pipe is corrosion-resistant and built for long-term performance, even in demanding industrial environments.

Q10: Why choose your heat pipe heat sink products?

As a reliable OEM heat sink manufacturer, we offer best heat pipe heat sinks with high thermal efficiency, customizable designs, and durable materials. Our solutions help maintain stable device operation, improve energy efficiency, reduce maintenance costs, and provide reliable thermal management for any application.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018