KINGKA’s FSW (Friction Stir Welding) Liquid Cold Plate Parts are engineered for advanced thermal performance in high-power electronic applications. Manufactured using precision aluminum and copper materials, these cold plates are designed to efficiently dissipate heat in electric vehicles, data centers, renewable energy systems, and more. With the FSW technique, we ensure superior joint strength, leak-proof performance, and minimal thermal resistance.

Friction Stir Welding (FSW) Process

Strong, defect-free welds between aluminum parts without melting, ensuring high mechanical strength and excellent heat conduction.

High Thermal Conductivity

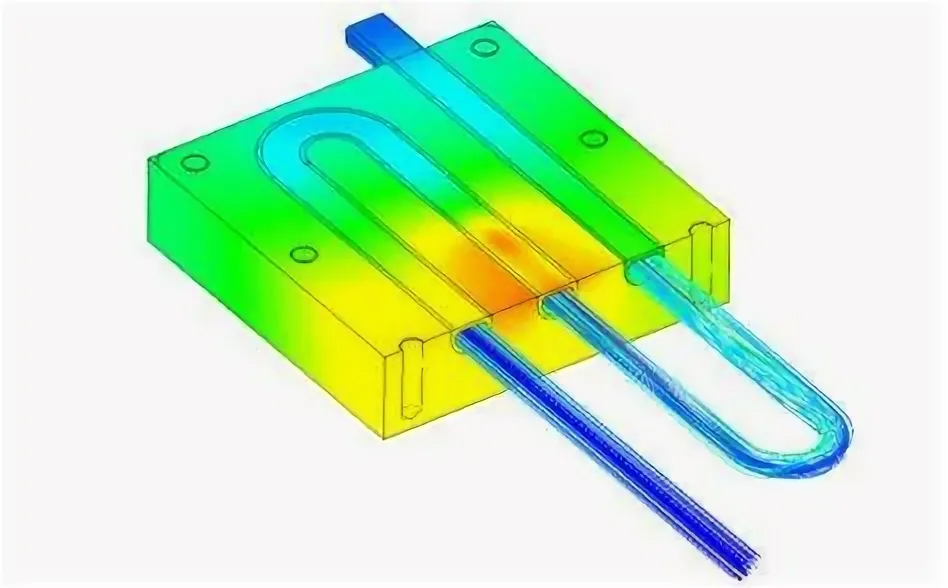

Efficient internal channel design for optimal liquid flow and maximum surface contact.

Leak-Proof Construction

Each unit undergoes helium leak detection to ensure 100% sealing performance.

Custom Machining Support

CNC precision machining of ports, threads, and surface interfaces with ±0.01 mm tolerance.

Lightweight & Durable

Aluminum alloy material offers excellent corrosion resistance, high strength, and reduced weight.

Tailored Cooling Solutions

Customized channel design and inlet/outlet layouts to suit your application needs.

| Parameter | Specification |

|---|---|

| Material | Aluminum 6061 / Copper C110 |

| Welding Method | Friction Stir Welding (FSW) |

| Tolerance | ±0.01 mm (machined surfaces) |

| Channel Design | Custom serpentine / parallel / pin-fin |

| Pressure Resistance | Up to 2.0 MPa |

| Leak Testing | Helium Mass Spectrometry |

| Finish Options | Anodizing / Powder Coating / Nickel Plating |

| Dimensions | Fully customizable |

| Connection Ports | G1/4, G3/8, Custom threads or quick-connects |

Electric Vehicle Battery Cooling

High-Power Inverters & IGBTs

5G Base Stations

Data Center Servers

Solar Inverters

Laser Systems

Industrial Automation Devices

Material Cutting – Laser cutting aluminum plates with ±0.05 mm precision

Channel Machining – CNC milling custom flow paths

FSW Welding – Strong, seamless aluminum plate bonding

Leak Testing – Helium detection for 100% leak-proof guarantee

Surface Finishing – Optional polishing, anodizing, coating

Final Machining – Ports, threads, mounting holes, labels

Assembly & Inspection – 3D measurement, pressure test, and quality validation

Certified Systems: ISO 9001:2015, IATF 16949 compliant

Full Inspection: CMM dimensional measurement, spectrometer material verification

Traceable Production: Barcode labeling, process tracking

Environmental Testing: Corrosion resistance, thermal cycling validation

Q1: What is the benefit of using FSW instead of traditional welding for cold plates?

A1: FSW avoids melting the metal, resulting in stronger joints, no porosity, and better thermal performance.

Q2: Can you customize the channel layout for my specific application?

A2: Yes, we offer full design customization based on your thermal simulation or performance goals.

Q3: What is the maximum size of a cold plate you can manufacture?

A3: We can produce cold plates up to 800mm in length, depending on material and design.

Q4: Do you support small-volume prototyping?

A4: Absolutely. We offer both prototyping and high-volume production services.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018