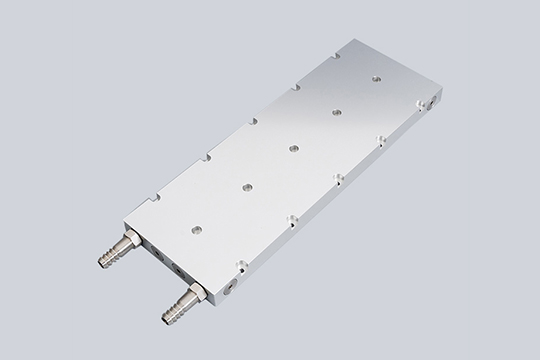

FSW Liquid Cold Plate Parts represent the next generation of thermal management solutions, engineered through advanced Friction Stir Welding (FSW) technology. By using a solid-state joining process, FSW allows for the production of liquid cold plate parts with superior structural integrity and optimized heat dissipation performance. This technology is widely applied in sectors where precise temperature control and long-term reliability are essential, such as power electronics, data centers, electric vehicles, medical devices, and aerospace systems.

As a leading Friction Stir Welding Cold Plate Manufacturer, KingKa specializes in the production of high-performance FSW Cold Plate Components that meet customized requirements for a variety of industries. We combine state-of-the-art FSW equipment, CNC Machining centers, and strict quality control processes to deliver custom FSW Liquid Cold Plate Parts with outstanding thermal management capabilities.

Our manufacturing process focuses on precision, consistency, and performance, ensuring each part contributes to the overall effectiveness of the FSW Liquid Cooling Plate system.

To manufacture high-quality FSW Liquid Cold Plate Parts, KingKa employs specialized equipment tailored for both joining and precision machining:

FSW Welding Machines: Provide high-strength, defect-free welding for consistent bonding between aluminum substrates, ensuring leak-free cooling channels.

High-Precision CNC Machining Centers: Allow for tight tolerance control and complex geometry processing on individual FSW Cold Plate Components.

Water Jet Cutting and Laser Cutting Machines: Enable smooth, burr-free contouring of cold plate materials before assembly.

Surface Finishing Equipment: Includes anodizing lines, grinding machines, and sandblasting cabinets for enhanced corrosion resistance and improved thermal conductivity.

Our production process for FSW Cold Plate Parts follows strict quality guidelines to ensure structural integrity and thermal efficiency:

Material Preparation: Selection of suitable base metals, commonly aluminum alloys like 6061, 6063, or 7075, based on application needs.

Precision Cutting: Raw materials are cut using laser cutting or water jet cutting methods for clean edges and dimensional accuracy.

Friction Stir Welding: Critical parts of the liquid cooling channels are joined using FSW, ensuring strong, porosity-free welds.

CNC Machining: After welding, milling, drilling, and surface flattening processes shape the cold plate parts to meet exact design tolerances.

Surface Treatment: Optional anodizing, sandblasting, or polishing improves corrosion resistance and aesthetic quality.

Quality Inspection: Every FSW Liquid Cold Plate Part undergoes dimensional and pressure testing to ensure leak-tightness and performance reliability.

KingKa primarily uses aluminum alloys for FSW Liquid Cold Plate Parts, including:

6061 Aluminum FSW Cold Plate Parts

6063 Aluminum Alloy Cold Plate Components

7075 High Strength FSW Cold Plate Parts

For industries with special material requirements, we also offer copper-based FSW Liquid Cold Plate Parts upon request.

Our machining precision typically meets tolerances within ±0.1mm, making these FSW Cold Plate Parts suitable for integration into high-precision cooling systems used in electronics, automotive battery packs, and industrial power modules.

To enhance both thermal performance and product durability, KingKa offers various surface treatment options for FSW Cold Plate Parts:

Anodizing: Adds corrosion protection and surface hardness.

Sandblasting: Improves surface roughness for better thermal paste adhesion.

Polishing: Reduces surface imperfections, boosting heat conduction efficiency.

KingKa’s FSW Liquid Cold Plate Parts serve a wide range of industries requiring liquid cooling technology:

Power Electronics: Used in IGBT modules, inverters, and power converters for efficient heat removal.

EV Battery Cooling: Integrated into Battery Management Systems (BMS) and EV powertrains for temperature regulation.

Data Centers: Essential for liquid-cooled server racks and telecommunication equipment requiring high heat flux dissipation.

Aerospace and Defense: Applied in satellite systems, avionics, and radar cooling units.

Medical Devices: Provide cooling for high-power laser systems and imaging equipment.

High Thermal Conductivity: Thanks to aluminum FSW design and optimized channel layout.

Leak-Proof Design: Achieved through defect-free FSW joints and rigorous pressure testing.

Lightweight Construction: Ideal for weight-sensitive applications like EVs and aerospace systems.

Strong Mechanical Bonding: No cracking or delamination under thermal cycling or vibration.

OEM Customization Support: Flexible for Custom FSW Cold Plate Parts production, from prototype runs to large-volume orders.

With years of expertise in Friction Stir Welding technology, advanced CNC capability, and dedicated OEM/ODM support, KingKa stands as a trusted FSW Cold Plate Manufacturer for global clients in electronics, automotive, renewable energy, and defense sectors.

From small-batch prototypes to high-volume production, KingKa delivers reliable, cost-effective, and precision-engineered FSW Liquid Cold Plate Parts to meet your thermal management challenges.

FSW Liquid Cold Plate Parts are thermal management components produced using Friction Stir Welding (FSW). This solid-state welding technique creates high-strength, leak-proof joints between aluminum layers, forming internal cooling channels for efficient liquid flow and heat dissipation.

Our FSW Cold Plate Components are primarily made from aluminum alloys such as 6061, 6063, and 7075, offering excellent thermal conductivity, strength, and lightweight characteristics. Copper materials are also available for special projects.

KingKa supplies FSW Liquid Cooling Plates to industries like:

Power Electronics (IGBT, Inverters)

Electric Vehicle (EV) Battery Cooling Systems

Data Centers and Telecom Equipment

Aerospace and Defense

Medical Devices (e.g., Laser Cooling, Imaging Equipment)

Yes. As a professional FSW Cold Plate Manufacturer, we offer OEM/ODM services. We can customize cold plate dimensions, channel patterns, inlet/outlet port locations, and surface finishes based on your project requirements.

We provide a range of surface finishing options, including:

Anodizing (for corrosion resistance)

Sandblasting (for better thermal paste adhesion)

Polishing (to reduce surface roughness)

Custom color anodizing (on request)

Every FSW Liquid Cold Plate Part undergoes strict dimensional inspections, helium leak testing, and pressure testing to ensure leak-free performance and thermal reliability, meeting both industrial and automotive quality standards.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018