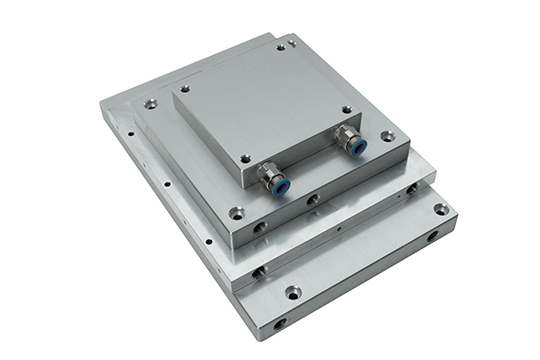

KINGKA specializes in the design and manufacturing of precision CNC machined liquid cold plates, critical components in modern thermal management solutions for high-power electronic devices and systems. Our liquid cold plates are custom fabricated with ultra-high precision using advanced 5-axis CNC Machining technology, delivering superior heat dissipation performance, reliability, and durability. They are engineered for applications requiring efficient liquid cooling such as data centers, power electronics, electric vehicles (EV), medical devices, aerospace, and industrial automation.

KINGKA’s Liquid Cold Plates are produced using cutting-edge 5-axis CNC milling machines capable of machining intricate microchannel liquid cooling passages and complex geometries with dimensional tolerances as tight as ±0.01 mm. This precision ensures optimal coolant flow, reduced pressure drop, and enhanced thermal transfer efficiency.

We manufacture liquid cold plates from premium aerospace-grade aluminum alloys (6061-T6, 7075) and high-purity copper, known for their excellent thermal conductivity, corrosion resistance, and mechanical strength. Material selection is tailored to your project requirements, balancing heat transfer performance and structural integrity.

Utilizing CFD (Computational Fluid Dynamics) simulations, our engineering team optimizes the internal channel design, enabling the fabrication of custom serpentine flow paths, vortex-enhanced channels, and microchannel arrays that maximize coolant turbulence and heat dissipation while minimizing fluid resistance.

We provide various surface treatments such as anodizing, electroless nickel plating, and powder coating to improve corrosion resistance, surface hardness, and aesthetic appeal, tailored for harsh operating environments.

Our liquid cold plates undergo stringent pressure testing (up to and beyond 10 bar) and leak testing to ensure reliability under high-pressure liquid cooling systems. The plates feature precise port threading and sealing surfaces compatible with industry-standard fittings and connectors.

| Specification | Details |

|---|---|

| Materials | Aluminum 6061-T6, Aluminum 7075, High-purity Copper |

| Manufacturing Process | 5-axis CNC milling with ±0.01 mm tolerance |

| Flow Channel Types | Microchannels, serpentine, vortex flow, customized |

| Surface Treatment Options | Anodizing, electroless plating, powder coating (optional) |

| Max Operating Pressure | ≥10 bar |

| Operating Temperature | -40°C to 150°C |

| Max Workpiece Size | Custom per client design |

Data Center & High-Performance Computing: Cooling of CPUs, GPUs, and server racks using liquid cold plates for enhanced thermal control and energy efficiency.

Power Electronics Thermal Management: Inverters, converters, and IGBT modules requiring effective liquid cooling to maintain stability and longevity.

Electric Vehicle (EV) Battery Cooling: High-performance battery pack cold plates ensuring safe temperature regulation and improved battery life.

Medical and Diagnostic Equipment: Precision cooling solutions for imaging systems, lab instruments, and critical medical electronics.

Aerospace & Defense Electronics: Lightweight and high-efficiency liquid cooling for avionics and mission-critical systems.

Industrial Automation: Thermal management for robotics, sensors, and control modules in harsh environments.

KINGKA operates a modern manufacturing plant equipped with over 30 advanced CNC machines, including multiple 5-axis centers dedicated to producing complex liquid cold plates with microchannel structures and ultra-precise features. Our CNC machining capabilities enable high-volume production with consistent quality and fast turnaround.

Our in-house engineering team leverages CFD thermal simulations and 3D CAD modeling to optimize liquid cold plate designs for enhanced thermal performance and manufacturability. We collaborate closely with clients to tailor custom solutions that precisely meet their thermal management challenges.

We implement a rigorous quality assurance process, including:

Coordinate Measuring Machine (CMM) inspections to verify dimensional accuracy

High-pressure leak and hydrostatic testing to guarantee seal integrity

Surface finish and roughness testing to ensure compliance with specifications

Material certification and traceability to ensure authenticity and performance

From rapid prototyping and pilot production to large-scale manufacturing, KINGKA provides flexible and scalable solutions tailored to your project’s budget and timeline. We support a wide range of batch sizes without compromising quality or delivery speed.

KINGKA offers full lifecycle support from concept design, prototype fabrication, CNC machining, surface treatment, assembly, and after-sales technical assistance. Our dedicated project managers ensure clear communication and on-time delivery, helping clients accelerate time-to-market.

Q1: What materials are used for your CNC machined liquid cold plates?

A1: We primarily use aerospace-grade aluminum alloys such as 6061-T6 and 7075, as well as high-purity copper, chosen for their excellent thermal conductivity, corrosion resistance, and mechanical strength.

Q2: What CNC machining capabilities does KINGKA have for liquid cold plates?

A2: KINGKA operates advanced 5-axis CNC machining centers capable of machining complex microchannel flow paths with tight dimensional tolerances up to ±0.01 mm, ensuring precise and efficient thermal management solutions.

Q3: Can the flow channels be customized?

A3: Yes, we provide custom flow channel designs including microchannels, serpentine paths, and vortex-enhanced channels optimized through CFD simulations to maximize heat transfer efficiency and minimize pressure drop.

Q4: What surface treatments are available?

A4: Available surface treatments include anodizing, electroless nickel plating, and powder coating to enhance corrosion resistance, surface durability, and aesthetic appearance.

Q5: What pressure ratings do your liquid cold plates support?

A5: Our cold plates are pressure-tested to withstand operating pressures of 10 bar or higher, ensuring reliable performance under demanding liquid cooling conditions.

Q6: Which industries commonly use your liquid cold plates?

A6: Industries include data centers, high-performance computing, power electronics, electric vehicles, medical devices, aerospace, defense, and industrial automation.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018