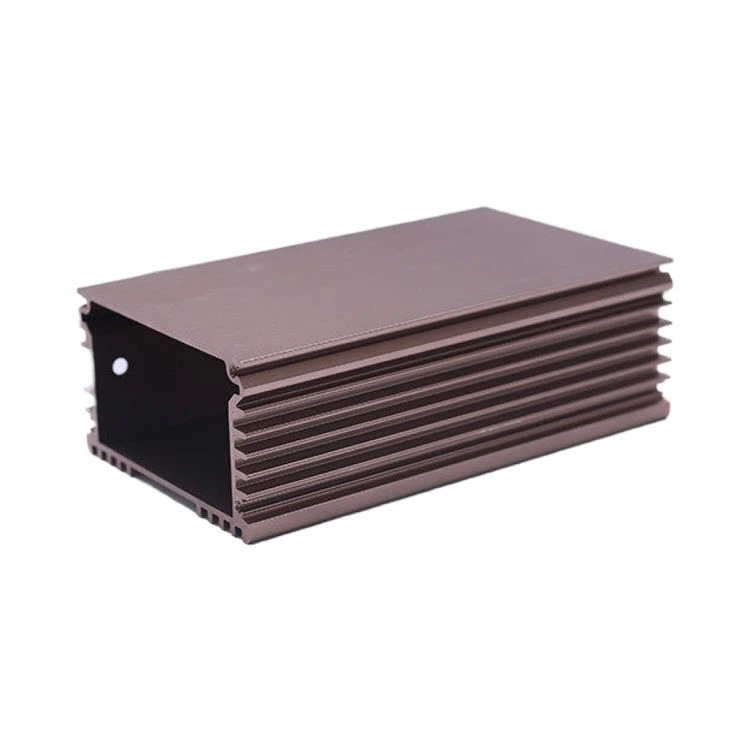

KingKa's high-quality extruded heat sinks are made of 6063/6061 aluminum alloy or copper through precision milling, drilling and threading to create complex heat sink fins and microchannel structures. They are used in electronic devices (CPU/GPU), new energy vehicles (batteries/headlights) and industrial systems (lasers/inverters), providing efficient and reliable heat dissipation solutions that meet stringent industry standards. Consult now for customization!

Key Features and CNC Machining Applications

Excellent Materials:

extruded heat sinks are primarily made from highly thermally conductive aluminum alloys (e.g., 6063, 6061) or copper. Aluminum is favored for its light weight and cost-effectiveness, while copper offers superior thermal conductivity under extreme heat loads.

CNC Precision Machining:

Complex Geometries: CNC milling and drilling techniques enable precise fabrication of complex fin arrays, microchannels, and custom profiles to maximize surface area and enhance convection.

Surface Finishing: CNC controlled tools achieve uniform roughness for improved thermal interface contact and coating adhesion.

Threaded Holes and Mounting Features: CNC ensures precise alignment of screw holes and brackets for seamless integration with PCBs or chassis.

Advanced Surface Finishing:

Anodizing: Electrochemical oxidation (e.g., black anodizing) increases emissivity (up to 0.9) and corrosion resistance, which is critical for LED lighting and outdoor applications.

Sandblasting: Increases surface roughness for enhanced airflow turbulence and heat dissipation efficiency.

Powder coating: provides aesthetic customization and additional protection from environmental wear and tear.

Applications across industries

High-quality extruded heat sinks are essential in the following areas:

Electronics: Cooling of CPUs, GPUs, and power modules in servers and telecommunications equipment

Automotive: Thermal management of electric vehicle batteries, LED headlights, and on-board chargers

Industrial systems: Cooling of laser diodes, power converters, and renewable energy inverters

Why KingKa?

KingKa leverages its expertise in CNC machining and material science to deliver extruded heat sinks that combine precision, durability, and thermal performance. Our solutions are designed to meet stringent industry standards and range from aircraft-grade aluminum alloys to customized surface finishes.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018