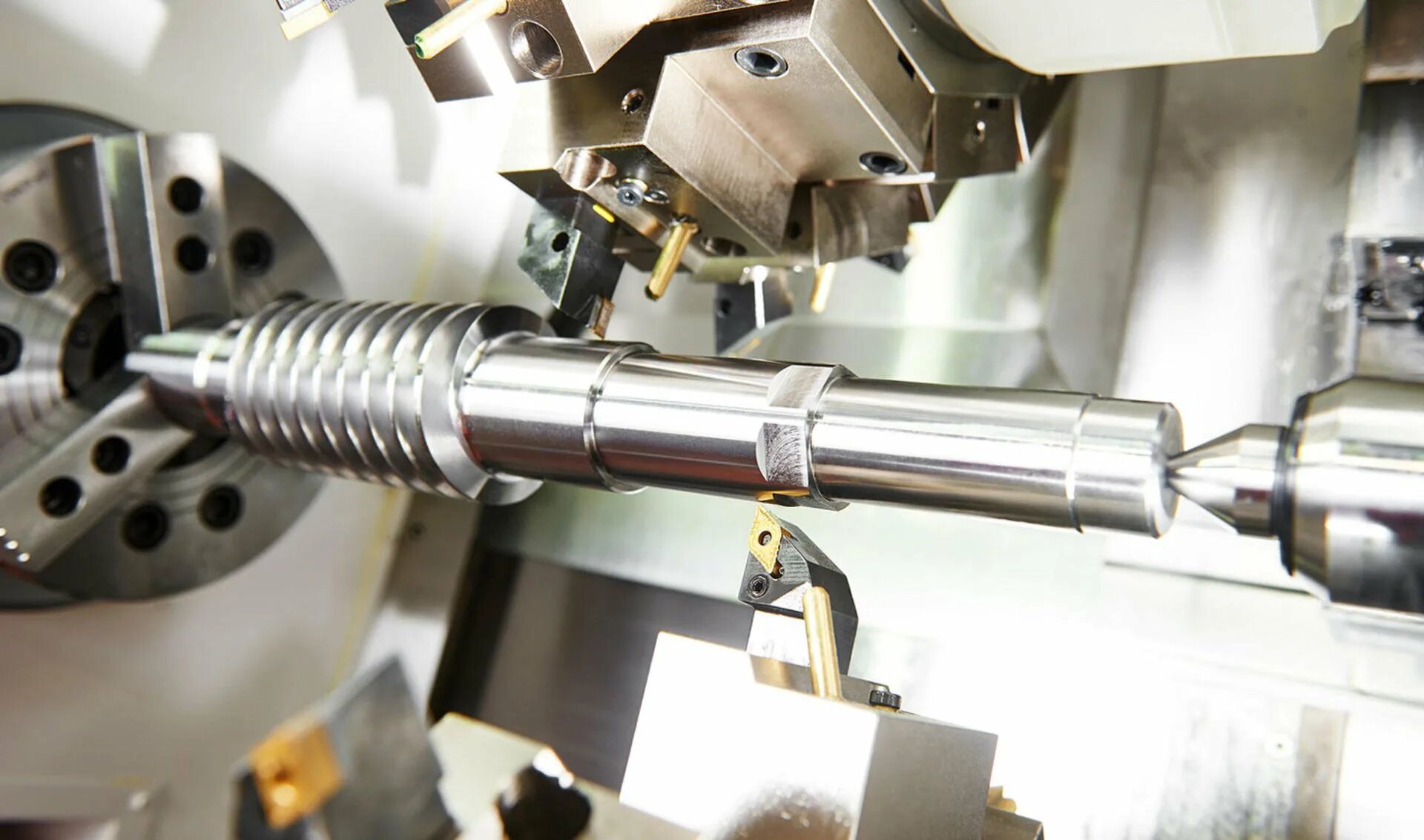

KINGKA is a trusted manufacturer with over 15 years of experience in precision machining and thermal management components. Our CNC Turning Parts are engineered for high accuracy, reliability, and performance—meeting the critical needs of industries including automotive, electronics, medical devices, aerospace, and renewable energy.

With over 38+ advanced machines, including high-speed CNC turning centers, skiving machines, and friction stir welding systems, KINGKA offers full-service CNC turning from prototyping to mass production with ±0.01 mm tolerances.

Industry-Leading Precision

CNC turning tolerances up to ±0.01 mm, repetition accuracy within ±0.005 mm

Complex geometries supported by multi-axis turning and live tooling

Ideal for shafts, bushings, connectors, couplings, and threaded components

Full Material Support

We machine a wide range of materials to suit any industry:

Metals: Aluminum (6061, 7075), Stainless Steel (SS304, SS316), Brass, Copper, Titanium

Plastics: POM, PTFE, Nylon, ABS, PE, PVC

Complete In-House Capabilities

Turning, milling, drilling, tapping, threading—all performed in-house

Surface finish options: polishing, anodizing, sandblasting, plating, black oxide

Seamless transition from concept to finished product

Design & Engineering Support

Our engineering team brings over 15 years of design experience and uses advanced CFD simulation and 3D modeling tools to optimize your parts for functionality, durability, and cost-efficiency. We offer:

End-to-end design collaboration

Structural and thermal simulation reports

DFMA (Design for Manufacturability and Assembly) review

Advanced Manufacturing Process

Our CNC turning parts are produced under a rigorous multi-step workflow:

Material Preparation – Precision laser cutting with ±0.05 mm accuracy

Stamping – Consistency ensured with up to 50 strokes/minute

CNC Turning – Tight tolerance machining using multi-axis lathes

Drilling & Tapping – Position and thread accuracy controlled within ±0.05 mm

Surface Finishing – Polishing, sandblasting, and grinding to Ra0.8 or better

Assembly – Integration of CNC parts into assemblies with ±0.2 mm alignment

Rigorous Quality Control

We ensure every CNC turning part meets the most demanding quality standards:

100% dimensional inspection using 3D optical systems

CMM inspection with up to 1.5μm accuracy

Spectrometer for material composition analysis

Leak, thread, and structural integrity testing

Certified by ISO 9001:2015 and IATF 16949, we guarantee quality for even the most regulated industries.

Our custom CNC turned components are used in:

Automotive: heat sink fittings, valve parts, brackets

Electronics: Signal connectors, custom housings, spacers

Medical: Implant prototypes, dental tools, surgical devices

Energy: Wind power parts, solar tracking fittings

Aerospace: Lightweight shaft components, thread-on covers

We also produce turned parts integrated into liquid cold plates and heat sink assemblies, making us a one-stop thermal solution provider.

To protect your CNC turned parts in transit, KINGKA offers:

Custom CNC-milled foam inserts

Anti-static and VCI protection for sensitive electronics

Sustainable packaging: biodegradable foams, recyclable boxes

Traceability: Barcode/RFID integration and drop-tested shipment solutions

With KINGKA, you gain more than a supplier—you gain a technical partner. Our mission is to empower your product innovation with:

Reliable turning precision

Robust supply chain execution

Proactive engineering support

Transparent project communication

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018