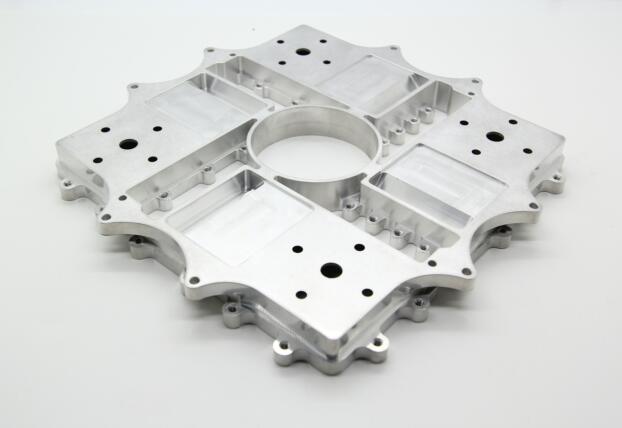

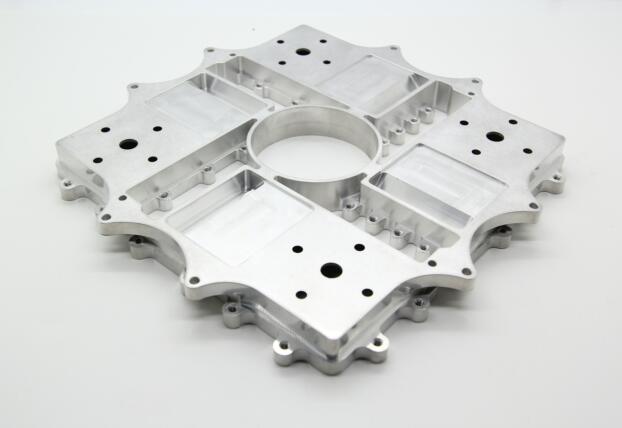

Our CNC Machined Aluminum Base Plate is a high-precision, custom-fabricated aluminum component designed to serve as a robust foundation or mounting platform for various industrial applications. Manufactured using state-of-the-art CNC Milling technology, this base plate offers exceptional dimensional accuracy, superior mechanical strength, and excellent corrosion resistance, making it ideal for industries such as automotive, electronics, aerospace, medical equipment, and automation.

Precision CNC Machining: Utilizing advanced multi-axis CNC Milling centers, the aluminum base plate is produced with tight tolerances up to ±0.01 mm, ensuring perfect fit and alignment for complex assemblies.

High-Quality Aluminum Alloys: Fabricated from premium-grade aluminum alloys such as 6061-T6 and 7075, which provide an excellent balance of strength, lightweight, and corrosion resistance.

Custom Surface Finishes: Options include anodizing, bead blasting, powder coating, and other surface treatments to improve wear resistance, aesthetics, and environmental durability.

Lightweight yet Strong: Aluminum offers a significant weight reduction compared to steel base plates while maintaining sufficient structural integrity for demanding applications.

Fully Customizable: Designed and manufactured according to client’s CAD drawings or prototypes, accommodating various sizes, hole patterns, and complex geometries.

| Specification | Details |

|---|---|

| Material | Aluminum 6061-T6, 7075 (customizable) |

| Manufacturing Process | CNC Milling (3-axis, 4-axis, 5-axis available) |

| Dimensional Tolerance | ±0.01 mm |

| Surface Treatment | Anodized, Bead Blasted, Powder Coated, Electropolished (optional) |

| Max Workpiece Size | Customizable based on equipment capability |

| Hardness (Depending on Alloy) | 60-150 HV |

| Operating Temperature Range | -40°C to 120°C |

| Weight Reduction | Approx. 30-40% lighter than steel alternatives |

Automotive Industry: Engine mounting brackets, transmission bases, and chassis components.

Electronics & Telecom: Housing bases for circuit boards, heat sinks, and electronic enclosures.

Automation & Robotics: Mounting plates for robotic arms, conveyor systems, and precision machinery.

Aerospace & Defense: Structural bases and fixtures requiring lightweight yet durable materials.

Medical Devices: Equipment bases and support plates with stringent quality and precision demands.

Renewable Energy: Battery pack bases, inverter mounts, and solar panel fixtures.

Our factory is equipped with cutting-edge CNC milling machines, including multi-axis centers capable of producing highly complex geometries with superior surface finishes. We utilize CAD/CAM software for precise toolpath programming and simulation to ensure defect-free machining and optimal material usage.

Every base plate undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to guarantee compliance with design specifications and quality standards such as ISO 9001 and IATF 16949.

We source aerospace-grade aluminum alloys known for their excellent mechanical properties and processability. Our metallurgical experts work closely with the production team to optimize material selection and heat treatment for specific customer requirements.

We offer full customization — from prototype development to mass production — including modifications in thickness, hole patterns, threaded inserts, and special surface treatments. Our engineering team collaborates with customers to refine designs for manufacturability and cost efficiency.

Our aluminum base plates significantly reduce weight compared to traditional steel bases, contributing to improved energy efficiency in transportation and machinery while maintaining high strength and durability.

Q1: What materials do you use for the aluminum base plates?

A1: We primarily use high-quality aluminum alloys such as 6061-T6 and 7075, which offer excellent strength, corrosion resistance, and machinability. Custom materials can also be accommodated based on client requirements.

Q2: What is the typical dimensional tolerance you can achieve?

A2: Our CNC machining process can achieve dimensional tolerances as tight as ±0.01 mm, ensuring high precision and repeatability for complex parts.

Q3: Can you customize the size and design of the base plates?

A3: Yes, we offer full customization according to your CAD drawings or samples, including size, thickness, hole patterns, and surface finishes.

Q4: What surface treatments are available?

A4: Common surface treatments include anodizing, bead blasting, powder coating, and electropolishing to enhance corrosion resistance and appearance.

Q5: What industries typically use your CNC machined aluminum base plates?

A5: Our base plates are widely used in automotive, aerospace, electronics, medical devices, automation, and renewable energy industries.

Q6: What is the lead time for production?

A6: Lead time depends on order quantity and complexity but typically ranges from 1 to 4 weeks. We also offer expedited prototyping services.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018