Liquid-cooled plates, widely known as cold plates, are critical components in modern thermal management systems where heat dissipation requirements exceed the capabilities of air cooling. A cooling plate removes heat directly from electronic devices, batteries, or industrial equipment by circulating liquid through internal channels, providing superior thermal performance compared with traditional cool plates or air-cooled heat sinks.

As power density continues to increase across applications such as electric vehicles, data centers, power electronics, and laboratory instruments, liquid cold plates have become an indispensable solution for maintaining system reliability, efficiency, and long-term performance.

What Is a Cold Plate and How Liquid Cold Plates Work

To understand what is a cold plate, it is best described as a thermally conductive metal plate—typically aluminum, copper, or stainless steel—engineered with internal flow paths for liquid circulation. During operation, heat generated by the device is conducted into the plate and transferred into the flowing coolant.

Cold plate cooling relies on the much higher heat capacity and thermal conductivity of liquids compared to air. As a result, liquid cooling plates and water cooling plates can remove heat more efficiently and maintain tighter temperature control. In most systems, water cold plates use deionized water or water-glycol mixtures to balance thermal performance and corrosion resistance.

Depending on system architecture, cold plates may be integrated into a closed-loop cold plate cooling system, connected to a cold plate chiller, or paired with chiller plates and heat exchangers. In temperature-controlled environments, refrigerated cold plates are often used to maintain stable, repeatable conditions for testing and laboratory processes.

Categories of Cold Plates by Cooling Method

Cold plates are commonly classified according to how the coolant is supplied and controlled:

Water cooled cold plates for industrial and electronic cooling systems

Chill plates designed to operate with externally regulated coolant temperatures

Lab cold plates and refrigerated cold plates used in research, calibration, and thermal testing applications

Each solution is selected based on operating temperature range, thermal load, and control accuracy requirements.

Internal Flow Path and Structural Design Options

The internal structure of a cold plate has a direct impact on heat transfer efficiency and pressure drop. Common designs include:

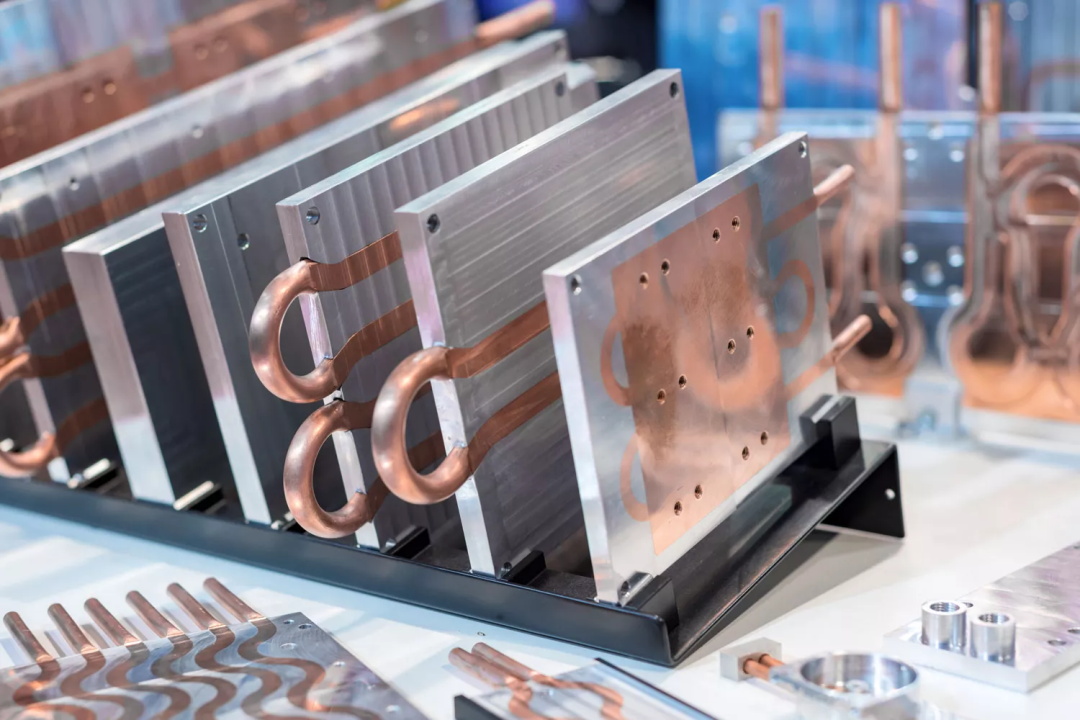

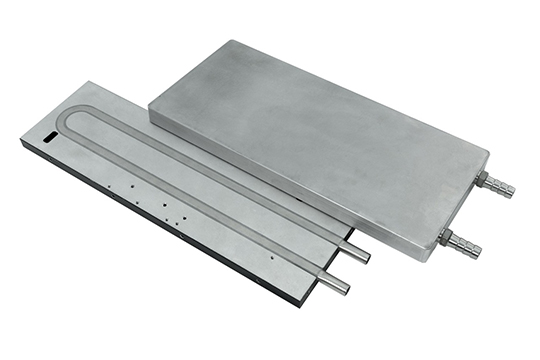

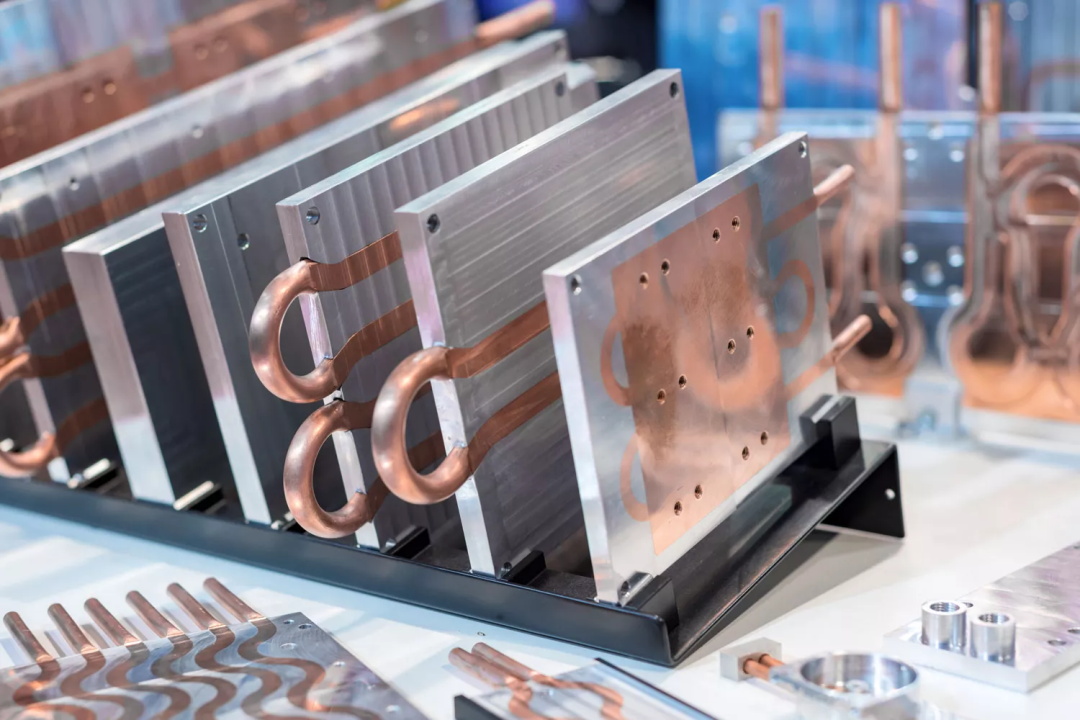

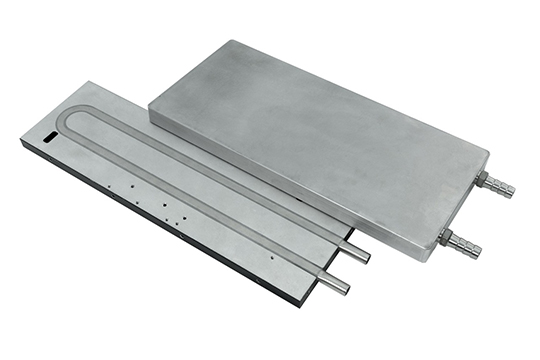

Tubed cold plates, where copper or stainless steel tubes are embedded into an aluminum base

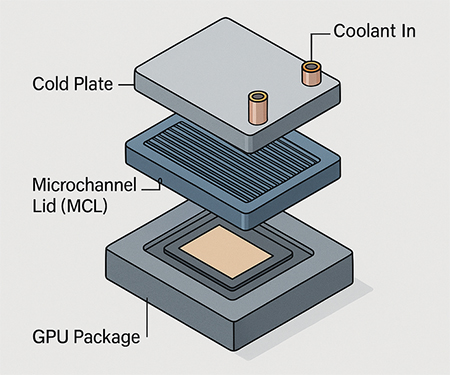

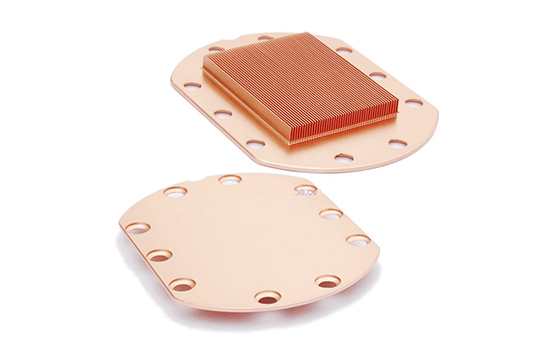

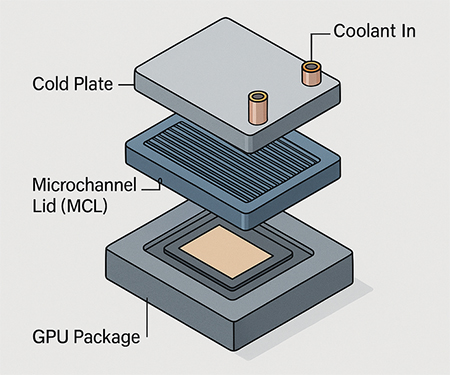

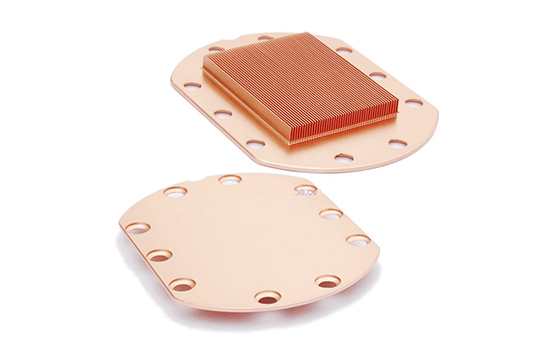

Microchannel cold plates and micro channel cold plates, which use narrow channels to maximize heat transfer surface area

Multi-pass and multi-circuit designs such as 2 pass cold plates, 4 pass cold plates, 6 pass cold plates, 7 circuit cold plates, 8 circuit cold plates, and 10 circuit cold plates

Multi-circuit designs are particularly effective for improving temperature uniformity across large cold plates, making them ideal for EV battery packs, power modules, and high-power server applications.

Material Selection for Cold Plates

Material choice directly affects thermal conductivity, mechanical strength, corrosion resistance, weight, and cost:

Aluminum cold plates and aluminum cooling plates (also referred to as aluminium cold plate or aluminium cooling plate) are lightweight, cost-effective, and widely used in automotive and electronics applications

Copper cold plates and copper cooling plates provide superior thermal conductivity for compact, high-heat-flux systems

Stainless steel cold plates and stainless steel cooling plates are selected for corrosive environments or special coolants where durability is critical

Selecting the correct material ensures long service life and stable thermal performance under continuous operation.

While standard cold plates are suitable for common applications, most industrial systems benefit from custom cold plates or custom liquid cold plates tailored to specific requirements. Customization allows optimization of channel layout, circuit count, port location, surface flatness, and mounting interfaces.

Both small cold plates for compact electronics and large-format plates for battery or data center cooling often require custom engineering to achieve optimal thermal and hydraulic performance.

Manufacturing Processes for Liquid Cold Plates

Several manufacturing methods are used depending on performance requirements and production volume:

CNC Machining and gun drilling for precision and design flexibility

Brazing for complex internal channel geometries

Friction stir welding for high-strength aluminum assemblies

Die casting for high-volume, cost-sensitive applications

Each process presents different trade-offs in thermal efficiency, scalability, and cost.

Typical Applications of Liquid Cold Plates

Liquid-cooled cold plates are widely applied in:

Electric vehicle battery thermal management

Data center servers and cold plate cooling systems

Power electronics, inverters, and converters

Medical equipment and lab cold plates

Industrial automation and laser systems

In all these fields, cooling plates, cold plates, and Liquid Cold Plate solutions provide reliable heat dissipation where air cooling is no longer sufficient.

From water cooled cold plates and microchannel cold plates to multi-circuit aluminum and copper designs, liquid-cooled plate technology plays a vital role in modern thermal management. Through careful design, material selection, and manufacturing optimization, custom cold plates deliver high efficiency, temperature uniformity, and long-term reliability across demanding industrial and electronic applications.

Frequently Asked Questions (FAQ) About Liquid Cold Plates

1. What is a cold plate?

A cold plate is a thermal management component designed to remove heat from electronic devices or industrial equipment through direct contact. It is typically made from aluminum, copper, or stainless steel and contains internal channels that allow liquid coolant to circulate. Compared with air cooling, cold plates provide significantly higher heat dissipation efficiency.

2. How do liquid cold plates work?

Liquid cold plates work by transferring heat from the heat source into a circulating liquid, such as water or a water-glycol mixture. Heat is conducted into the plate material and then carried away by the coolant flowing through internal channels. This process, known as cold plate cooling, enables precise temperature control in high-power and high-density applications.

3. What is the difference between a cold plate and a cooling plate?

The terms cold plate and cooling plate are often used interchangeably. In industrial and thermal engineering contexts, both refer to liquid-cooled heat exchangers used to remove heat from components. However, “cold plate” is more commonly used when referring to liquid-based systems, while “cooling plate” may also describe air-assisted designs.

4. When should I choose a liquid cooling plate instead of air cooling?

A liquid cooling plate is recommended when:

Heat flux is too high for air cooling

Space is limited and large heat sinks are impractical

Temperature uniformity is critical

Noise or fan power consumption must be minimized

In these cases, water cooling plates or water cooled cold plates offer superior thermal performance and stability.

5. What materials are used for cold plates?

Common materials include:

Aluminum cold plates / aluminum cooling plates for lightweight and cost-effective solutions

Copper cold plates / copper cooling plates for maximum thermal conductivity

Stainless steel cold plates / stainless steel cooling plates for corrosive environments or specialized fluids

Material selection depends on thermal requirements, coolant type, weight limits, and budget.

6. What is a microchannel cold plate?

A microchannel cold plate (or micro channel cold plate) features very small internal channels that greatly increase heat transfer surface area. These designs are ideal for high heat flux applications such as power electronics, CPUs, GPUs, and laser systems, but they require precise flow control and clean coolant.

7. What do “pass” and “circuit” mean in cold plates?

“Pass” and “circuit” describe the internal flow path design:

2 pass, 4 pass, and 6 pass cold plates refer to how many times coolant flows across the plate before exiting

7 circuit, 8 circuit, and 10 circuit cold plates divide flow into multiple parallel paths

Multi-pass and multi-circuit designs improve temperature uniformity, especially in large cold plates.

8. What is the difference between standard and custom cold plates?

Standard cold plates are pre-designed and suitable for general applications.

Custom cold plates or custom liquid cold plates are engineered for specific heat loads, mounting constraints, and flow requirements. Custom designs offer better thermal performance, optimized pressure drop, and improved system integration.

9. What is a cold plate chiller?

A cold plate chiller is a temperature-controlled cooling system that supplies coolant to cold plates. It is commonly used with chiller plates, refrigerated cold plates, and lab cold plates where precise and stable temperatures are required for testing, research, or sensitive equipment.

10. What is a tubed cold plate?

A tubed cold plate uses embedded copper or stainless steel tubing bonded into a metal base, typically aluminum. This design offers good reliability and moderate performance and is often used in lower-cost or lower-pressure applications.

11. Are liquid cold plates suitable for small devices?

Yes. Small cold plates are widely used in compact electronics, power modules, and medical devices. With proper design, even small liquid cold plates can dissipate significant heat while maintaining stable temperatures.

12. What industries use liquid-cooled cold plates?

Liquid-cooled cold plates are commonly used in:

Electric vehicle battery systems

Data centers and cold plate cooling systems

Power electronics and inverters

Medical and laboratory equipment

Industrial automation and laser applications