In modern industries such as automotive, electronics, and renewable energy, efficient thermal management is critical to system performance and reliability. Liquid cooling plates—also referred to as liquid cold plates or water cooling plates—play a vital role in dissipating heat from high-performance equipment. At KINGKA, a trusted manufacturer with 15 years of experience in thermal management solutions, we specialize in custom Liquid Cold Plate design to meet the precise requirements of our clients.

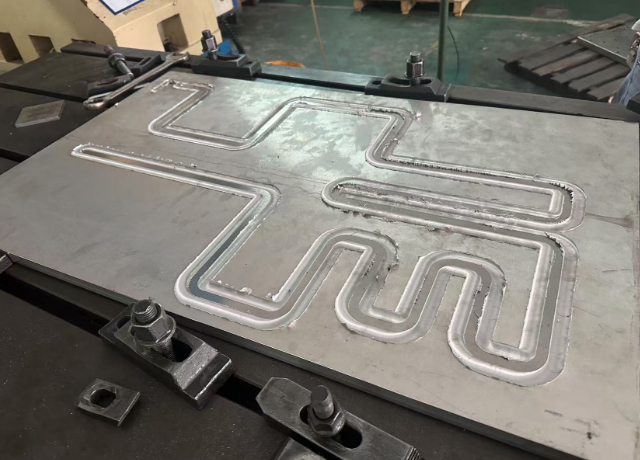

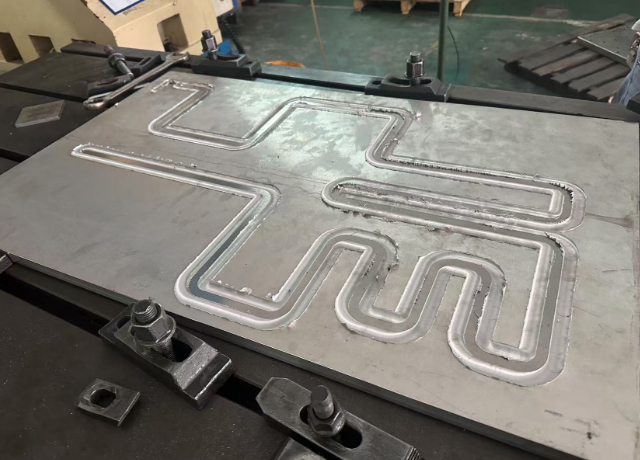

Liquid cooling plates are engineered to maximize heat transfer while maintaining durability and reliability. Typically, a liquid cold plate consists of an aluminum substrate with embedded copper tubes. The manufacturing process often begins with CNC Milling to create precise grooves in the aluminum. Copper tubes, pre-bent into the desired configuration, are then pressed onto the aluminum using specialized machinery. To minimize thermal resistance, gaps between the tubes and the aluminum are filled with epoxy resin. This combination leverages aluminum’s lightweight properties and copper’s excellent thermal conductivity.

For certain applications, advanced joining methods such as Friction Stir Welding (FSW) or Vacuum Brazing may be employed. Following assembly, inlets and outlets are installed to allow the circulation of liquid refrigerants, typically water or a water-alcohol mixture. The high thermal conductivity and specific heat capacity of water make it ideal for cold plate liquid cooling applications, while alcohol helps prevent freezing in low-temperature environments.

At KINGKA, we also provide custom liquid cold plates and large cold plates, tailored to meet specific project requirements, from compact designs for electronics to large-scale solutions for industrial machinery.

Why Liquid Leakage Must Be Prevented

A critical concern in liquid cooling plate applications is the potential for liquid leakage. Even minor leaks can lead to:

Reduced cooling efficiency, hindering heat dissipation

Damage to sensitive components, impacting system reliability

Corrosion of electronic circuits, increasing the risk of system failure

Common Causes of Leakage

Several factors can contribute to leakage in liquid cold plate design:

Material Stress and Surface Tension: Welding or joining processes can induce stress, creating micro-cracks that allow coolant to seep through.

Installation and Process Deficiencies: Imperfect sealing, aging silicone rings, or uneven aluminum surfaces can compromise system integrity.

Environmental Factors: Temperature fluctuations and high-pressure conditions can affect seals, leading to leaks that might only appear under real-world conditions.

Wettability Issues: Surface roughness or microscopic defects may allow coolant to penetrate more easily, increasing the risk of leakage.

Testing to Ensure Reliability

At KINGKA, we employ rigorous testing methods to mitigate leakage risks. Differential pressure tests and holding pressure tests, typically lasting 30 minutes to 2 hours, simulate real-world operating conditions. Adjusting water temperature during testing helps ensure that the water cooling plate performs reliably under thermal stress and cold shock scenarios.

With over 38 advanced machines, including CNC systems, skiving, and friction stir welding equipment, KINGKA ensures precise production from prototyping to mass delivery. Our dedication to liquid cold plate design combines cutting-edge technology with skilled craftsmanship, enabling us to produce high-performance liquid cooling plates, water cooling plates, and large cold plates that meet the exacting demands of diverse industries.

By focusing on innovative design, quality control, and customized solutions, KINGKA delivers custom liquid cold plates that enhance heat dissipation, protect critical components, and ensure long-term system reliability.

At KINGKA, we are committed to driving innovation and excellence in every product we deliver, providing cost-effective, high-quality thermal management solutions to clients worldwide.