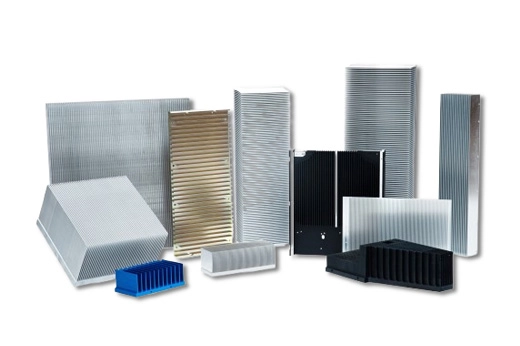

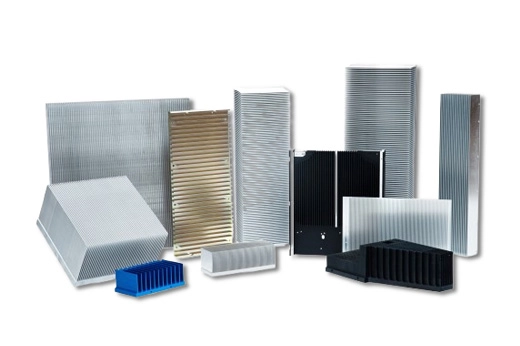

Have you ever wondered how electric vehicles can deliver immense power without battery overheating, or how massive data centers operate 24/7 without thermal failures? The answer lies in advanced thermal management engineering. At KINGKA, we leverage 15 years of experience in thermal solutions and precision machining to deliver cutting-edge Skived Fin Heat Sinks, extruded heat sinks, custom liquid cold plates, and complete thermal management systems for industries including automotive, electronics, renewable energy, and high-performance computing.

Skived vs. Extruded Heat Sink: Making the Critical Choice

One of the most important decisions in thermal design is choosing between Skived vs. Extruded Heat Sink technologies. This choice impacts cooling efficiency, device reliability, and overall cost.

Extrusion Heat Sinks: Made by pushing aluminum through a die, extrusion offers a cost-effective, consistent solution for low-to-medium heat loads. They are widely used in consumer electronics, LED lighting, and standard power electronics. Extrusion is limited by the physical constraints of fin height, thickness, and spacing, which caps the maximum surface area and cooling efficiency. Typically, the aspect ratio (fin height to gap) is limited to 8:1, restricting performance in high-density heat scenarios.

Skived Fin Heat Sinks: Created by precisely slicing and bending fins from a solid copper or aluminum block, skiving allows ultra-high fin density, taller and thinner fins, and minimal pitch, maximizing surface area. The monolithic design ensures zero thermal resistance between base and fins. Copper skived heat sinks, for example, have nearly double the thermal conductivity of aluminum, offering superior performance for high-power, space-constrained applications such as EV battery inverters, 5G telecom base stations, and photovoltaic inverters.

Case Example:

For a client developing a high-power EV inverter, a standard Extrusion Heat Sink was insufficient for peak heat loads. KINGKA engineered a custom skived fin solution, using copper with 0.4 mm fins and a 1.0 mm pitch, achieving a surface area more than triple that of the previous extruded design. This dramatically improved thermal performance while keeping the footprint compact.

Precision Engineering with KINGKA

CNC Machining forms the backbone of our high-precision fabrication. KINGKA uses advanced 5-axis CNC machines and skiving systems to produce heat sinks with ultra-tight tolerances (±0.01 mm), ensuring optimal thermal contact and structural integrity. Key manufacturing capabilities include:

Heat sinks: Base plates, fin arrays, and fully integrated Skived Heat Sinks.

Custom liquid cold plates: Leak-proof designs with complex internal channels for direct heat transfer.

Hybrid solutions: Combining heat pipes, fins, and cold plates for enhanced thermal distribution.

Two-phase cooling systems: Using vapor chambers and phase-change mechanisms for extreme heat loads.

KINGKA’s Advanced Thermal Solutions in Action

Client 1: Automotive Battery Cooling

Challenge: EV battery modules required tight temperature control to prevent degradation under high load.

Solution: Custom skived fin heat sinks integrated with heat pipes and a liquid cold plate.

Outcome: Reduced battery hotspot temperature by 15°C, increased module reliability, and extended battery life.

Client 2: 5G Base Station Electronics

Challenge: Compact high-frequency electronics generated localized heat beyond extrusion capabilities.

Solution: High-density Skived Fin Heat Sink design with optimized fin geometry through CNC machining and thermal simulation.

Outcome: Heat dissipation improved by 30%, allowing continuous 24/7 operation under high loads.

Client 3: Renewable Energy Inverters

Challenge: Photovoltaic inverters required precise thermal control in harsh environments (-40°C to 150°C).

Solution: Combination of Skived Fin Heat Sinks, heat pipes, and custom liquid cold plates.

Outcome: Enhanced thermal stability, reduced system throttling, and improved conversion efficiency.

Why Skived Fin Heat Sinks Outperform Extruded Heat Sinks

Surface Area Maximization: Skiving produces taller, thinner fins with minimal pitch, maximizing contact with airflow.

Monolithic Thermal Path: Continuous metal from base to fins eliminates thermal resistance.

Material Flexibility: Copper or aluminum choices allow tailored thermal conductivity.

Rapid Prototyping: No expensive dies are needed, enabling fast iteration and design optimization.

High-Power Applications: Perfect for EV inverters, BESS, data centers, and high-performance computing where Extruded Heat Sinks cannot meet thermal demands.

Thermal Performance Comparison:

| Feature | Extrusion Heat Sink | Skived Copper Heat Sink | KINGKA Custom Solution |

|---|

| Fin Height | 25 mm | 50 mm | 50 mm |

| Fin Thickness | 1.5 mm | 0.4 mm | 0.4 mm |

| Fin Pitch | 3.0 mm | 1.0 mm | 1.0 mm |

| Fin Count | 22 fins | 71 fins | 71 fins |

| Surface Area | ~2,300 cm² | ~7,200 cm² | ~7,200 cm² |

| Thermal Improvement | Baseline | +213% | +213% |

Beyond Air Cooling: Two-Phase and Liquid Solutions

When high-density fins reach air cooling limits, KINGKA provides solutions like custom liquid cold plates and two-phase cooling systems. These include:

Liquid cold plates: Cool components directly via internal channels with water-glycol or dielectric fluids.

Two-phase cooling: Heat pipes and vapor chambers transfer large heat loads efficiently using phase-change physics.

Example: A high-frequency inverter project used Skived Heat Sinks combined with a liquid cold plate, achieving a 30% performance increase over air-cooled solutions.

One-Stop Customization Services at KINGKA

R&D and Design:

Advanced Manufacturing:

±0.01 mm tolerance CNC machining.

Skiving, sheet metal forming, and cold plate integration.

High-performance surface finishing.

Quality Assurance:

ISO 9001:2015 and IATF 16949 certified processes.

3D optical inspection, CMM, leak testing, and infrared thermography.

Packaging & Logistics:

Custom foam inserts, anti-static and shock protection, sustainable packaging, RFID/barcode tracking.

KINGKA Advantage

With Skived Fin Heat Sinks, Extruded Heat Sinks, custom skived fin solutions, heat pipes, liquid cold plates, and two-phase cooling systems, KINGKA delivers optimized thermal management across diverse industries. Equipped with 38+ advanced machines including CNC, skiving, and friction stir welding, we ensure top-quality production from prototyping to mass delivery.

Clients benefit from lower thermal resistance, higher reliability, enhanced performance, and cost-effective custom solutions, even in extreme operating conditions.

Contact KINGKA today for expert consultation and custom thermal solutions that unlock your product’s full potential.