Effective Thermal Management is vital to ensuring the performance and longevity of electronic devices and industrial systems. Among the most widely used cooling solutions are heatsinks and Cold Plates. Understanding the differences between these two options can help you make an informed decision when choosing a cold plate supplier or Heatsink Manufacturer.

What Is a Heatsink?

Definition and Function:

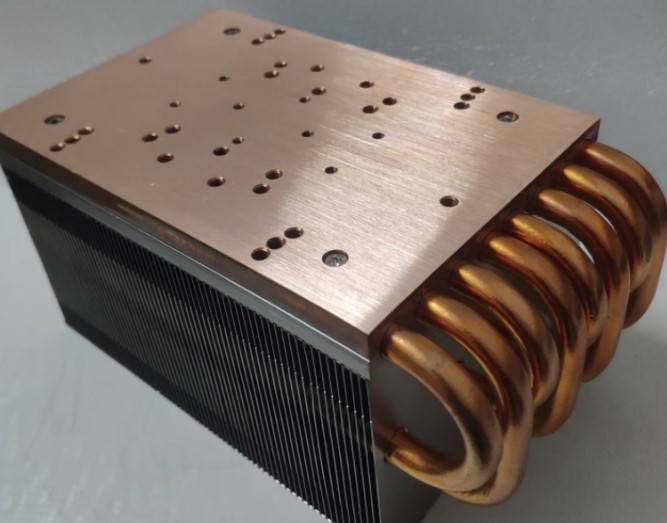

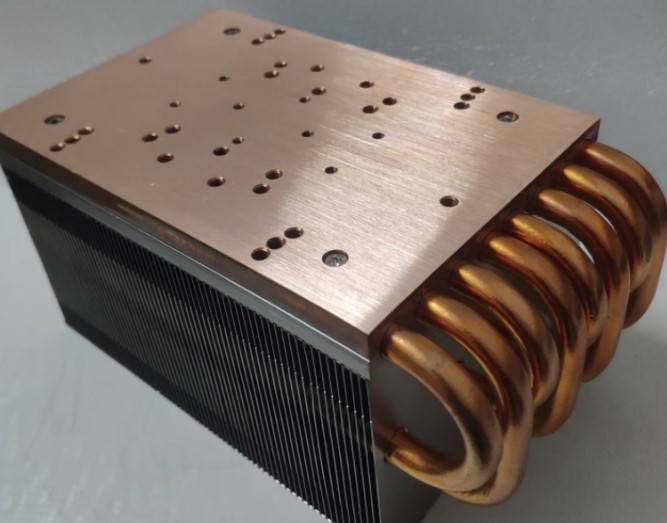

A heatsink is a passive heat exchanger that transfers heat generated by a device to a surrounding fluid—usually air. It dissipates heat via conduction (from the heat source to the heatsink) and convection (from the heatsink to the air), helping prevent overheating.

Types of Heatsinks:

Passive Heatsinks: Rely solely on natural air convection; typically include fins or pins to increase surface area.

Active Heatsinks: Equipped with fans or blowers to enhance cooling through forced air movement.

Materials and Properties:

| Material | Thermal Conductivity (W/m·K) | Advantages | Disadvantages |

|---|

| Aluminum | 205 | Lightweight, economical | Lower thermal conductivity than copper |

| Copper | 385 | Excellent thermal conductivity | Heavier, more expensive |

Applications:Electronics: Cooling CPUs, GPUs, and other integrated circuits.

LED Lighting: Managing heat in high-power LED applications.

Power Systems: Dissipating heat in inverters, power supplies, etc.

What Is a Cold Plate?

Definition and Function:

A cold plate uses liquid coolant to absorb and transfer heat away from components. Heat moves from the device to the plate via conduction, and the coolant carries it away via convection.

Types of Cold Plates:

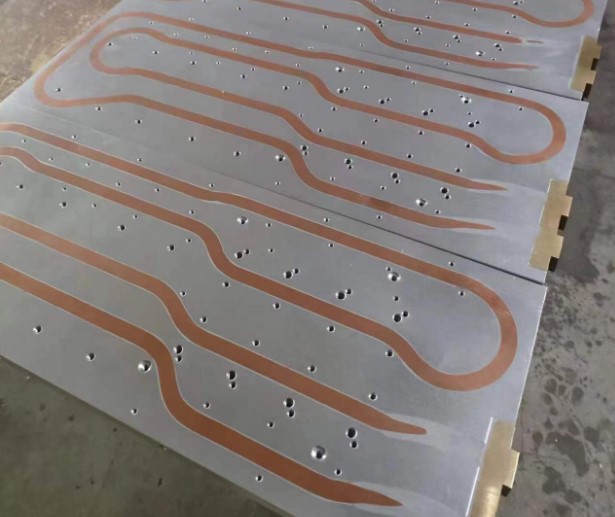

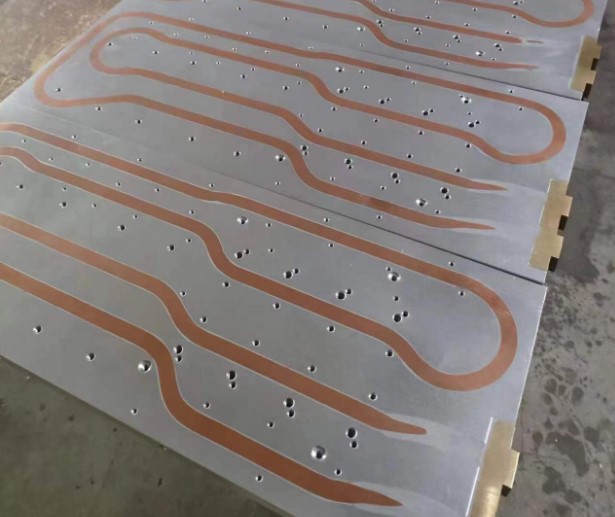

Tubed Cold Plates: Use embedded tubing (e.g., serpentine patterns) for coolant circulation.

Brazed Cold Plates: Comprise multiple metal layers joined with brazing, creating internal flow paths.

Friction Stir Welded Cold Plates: Utilize advanced welding techniques for precise coolant channel design.

Materials and Properties:

| Material | Thermal Conductivity (W/m·K) | Advantages | Disadvantages |

|---|

| Aluminum | 205 | Lightweight, corrosion-resistant | Lower thermal conductivity than copper |

| Copper | 385 | Excellent thermal conductivity | Heavier, more expensive |

Applications:

High-Power Electronics: Ideal for cooling IGBTs, power transistors, and other high-heat devices.

Laser Equipment: Ensures efficient heat dissipation in laser systems.

Medical Imaging: Maintains consistent temperature for diagnostic instruments.

Heatsinks vs. Cold Plates: Key Differences

| Feature | Heatsinks | Cold Plates |

|---|

| Cooling Method | Air cooling (natural or forced) | Liquid cooling (using coolant) |

| Performance | Moderate thermal performance | Superior thermal performance |

| Design Complexity | Simple structure with fins/pins | Complex internal flow channels |

| Maintenance | Low maintenance, easy to install | Requires pumps, reservoirs, regular upkeep |

| Cost | Lower cost, suitable for most needs | Higher cost, better for high-power systems |

Choosing the Right Solution for Your Application

Factors to Consider:

Heat Load: Use a heatsink for moderate loads; cold plates are better for high thermal output.

Size & Weight Constraints: Heatsinks are generally lighter and more compact.

Environmental Conditions: Cold plates perform better in low-airflow environments.

Budget: Heatsinks offer cost savings; cold plates provide better ROI for critical applications.

Industry Use Cases:

Data Centers: Cold plates support dense server cooling.

Automotive: Heatsinks for general electronics; cold plates for EV power systems.

Medical Devices: Cold plates ensure precise and stable thermal environments.

The thermal management field is rapidly evolving, with innovations enhancing both heatsinks and cold plates:

Advanced Materials: New composites and alloys are improving thermal conductivity.

Microchannel Cold Plates: Provide enhanced cooling efficiency via fine flow paths.

Hybrid Cooling Solutions: Combine air and liquid technologies for optimal results.

Selecting the right cooling method—heatsink or cold plate—depends on your specific application needs. Heatsinks are cost-effective and simple, ideal for most consumer and industrial electronics. Cold plates offer higher thermal performance and are suited for high-power or sensitive systems. By understanding these technologies and considering performance, complexity, and cost, you can confidently choose the right solution from a trusted heatsink or cold plate manufacturer.