In modern electronic devices, automobiles, aerospace and industrial systems, temperature control is always an important challenge that engineers must face. As devices become more powerful and more compact, how to efficiently dissipate heat in a limited space has become a core problem. Heat Pipes, this inconspicuous but efficient passive heat dissipation technology, is the key tool to solve this problem.

What is a heat pipe?

In simple terms, a heat pipe is a device that can conduct heat very efficiently, and its heat conduction efficiency can be up to 10,000 times that of a solid copper rod of the same size. Heat pipes do not rely on traditional metal heat conduction, but rather use the "evaporation-condensation" process of liquids to quickly move heat from one place to another.

Each heat pipe is vacuum-sealed inside and contains a specific working liquid (such as water, ethanol, naphthalene, etc.) and a capillary structure (similar to a micro sponge). When heat contacts one end of the heat pipe (called the "evaporation section"), the working liquid evaporates into gas, quickly moves to the colder end (the "condensation section") with heat, and then releases heat and liquefies. The capillary structure then brings the liquid back to the hot end, and this process continues to circulate without any external power supply.

This design, which cleverly utilizes the latent heat of phase change, makes the heat pipe a silent, passive, but extremely efficient Thermal Management tool.

Key Heat Pipe Reference Guide

| Heat Pipe Type | Temperature Range | Best Applications | Key Advantage |

|---|

| Water-based | 20°C to 150-200°C | Consumer electronics, data centers | High performance in common temperature ranges |

| Ethanol-based | -10°C to 100°C | Low-temperature environments, refrigeration | Works below freezing temperatures |

| Naphthalene-based | 200°C to 400°C | Industrial equipment, high-temp electronics | Extreme heat tolerance |

| Vapor chambers | 20°C to 150°C | Smartphones, thin devices | Better heat spreading for flat surfaces |

Classification by shape and structure:

Cylindrical heat pipe: traditional structure, suitable for long-distance heat conduction.

Flat heat pipe: suitable for embedding in thin devices such as notebooks.

Vapor Chamber: efficient heat dissipation on a flat surface, suitable for compact devices such as smartphones.

Loop Heat Pipe: separates vapor and liquid paths, with stronger performance, suitable for high-power applications.

Special design:

Pulsating heat pipe: no capillary structure, relying on gas-hydraulic pressure difference to promote the circulation of working fluid.

Variable conduction heat pipe: can adjust the heat conduction rate and maintain a constant temperature.

Micro heat pipe: designed for micro electronic components.

Material selection and compatibility

Common materials for heat pipe housings include copper, aluminum, and stainless steel. Copper has excellent thermal conductivity and is often paired with water for electronic cooling; aluminum is lighter and suitable for aerospace or portable devices; stainless steel is used in high-temperature or corrosive environments.

Compatibility between the material and the working fluid is critical. For example, if the liquid reacts chemically with the pipe wall, non-condensable gases will be generated, which will destroy the heat pipe cycle efficiency and even cause failure. Therefore, when designing heat pipes, the material combination must be strictly selected.

Wide Application of Heat Pipes

1. Consumer Electronics: Cooling Compact Devices

Heat pipes have become a standard for cooling solutions for laptops, game consoles, tablets, and mobile phones. For example, the ultra-thin heat spreader used in smartphones not only keeps the processor cool, but also ensures that the device will not get hot in high-performance mode.

2. Data Centers and Servers: Supporting High-Density Computing

In data centers and edge computing devices, heat pipe radiators can achieve higher server density and lower energy consumption. Its high reliability avoids the risk of downtime caused by fan or pump failure.

3. Automotive and electric vehicles: Next-generation thermal management solutions

In the field of electric vehicles, heat pipes are used for thermal management of battery packs, power electronics, inverters, and motor control modules to improve safety and extend system life.

4. Aerospace and satellites: Coping with extreme environments

Because heat pipes do not rely on gravity to operate, they are very suitable for space applications such as space stations and satellites. For example, they are used to manage extreme temperature changes in satellites under sunlight and earth's shadow.

5. Industrial systems: Improving operational stability

Heat pipe technology is widely used in industrial power supplies, LED lighting, laser equipment, and solar inverters to replace traditional air-cooled or water-cooled systems, reduce maintenance, and improve reliability.

Advantages and limitations of heat pipes

Advantages:

Extremely high thermal conductivity

No electricity required, completely passive operation

No noise, suitable for silent applications

Long service life, can operate for decades

Customizable design, suitable for various installation environments

Limitations:

There is an upper limit on heat flow (capillary limit, boiling limit, etc.)

Some structures are sensitive to installation direction

Temperature range is limited by working fluid

If the hot end continues to overheat, it may cause dry-out failure

Therefore, in the design, it is necessary to combine factors such as heat load, direction, and working environment to select a suitable heat pipe solution.

Heat Pipes vs. Vapor Chambers: What’s the Difference?

Basic Structural Differences

Though related technologies, heat pipes and vapor chambers differ in fundamental ways:

| Feature | Heat Pipes | Vapor Chambers |

|---|

| Shape | Cylindrical or flattened tubes | Flat, planar sheets |

| Heat Transfer Pattern | Linear (point-to-point) | Planar (spreads in two dimensions) |

| Orientation Sensitivity | Often benefits from gravity assistance | Less sensitive to orientation |

| Typical Applications | Moving heat over distances | Spreading heat from a concentrated source |

| Integration Complexity | Moderate | Higher |

The most significant difference lies in how they distribute heat. Heat pipes excel at transferring heat from one location to another, while vapor chambers excel at spreading heat from a concentrated source across a larger surface area.

Heat pipes make heat dissipation "invisible but powerful"

The reason why heat pipes are called "silent heat dissipation heroes" is that they are silent and passive, but can stably and efficiently manage heat, protecting electronic devices in many industries. From laptops to satellite aircraft, from game consoles to electric vehicles, heat pipes are quietly pushing thermal management technology to higher standards.

As electronic devices continue to develop towards miniaturization and high performance, heat pipe technology will continue to iterate and become an indispensable force in future heat dissipation solutions.

FAQ

Q1: Do heat pipes require power to operate?

A1: No. Heat pipes are a completely passive thermal management device that conducts heat through the evaporation and condensation phase change process of liquids without the need for electrical drive.

Q2: Can heat pipes be installed at any angle?

A2: Most heat pipes are affected by gravity and perform best in the vertical direction (hot end at the bottom, cold end at the top). However, through structural optimization (such as using loop heat pipes), reliable operation at any angle or even in zero gravity can be achieved.

Q3: How long is the service life of heat pipes?

A3: Under normal use conditions, heat pipes have almost no mechanical wear and can last for more than 10 years. The key lies in the packaging quality, material compatibility, and the stability of the operating environment.

Q4: What sizes and shapes are available for heat pipes?

A4: Heat pipe sizes and shapes are highly customizable, including diameter, length, curved shape, flat structure, heat sink, etc., suitable for various structural constraints and thermal management requirements.

Q5: Are heat pipes suitable for high temperature or extreme environments?

A5: Yes. By choosing different working fluids (such as sodium, naphthalene, ammonia) and materials (such as stainless steel, nickel-based alloys), heat pipes can work stably in an environment of -50°C to 500°C, and are widely used in high-end scenarios such as aerospace, military industry, and energy.

Among many heat pipe suppliers, Kingka has become a trusted partner of many industry customers with its deep technical accumulation, advanced manufacturing technology and perfect customer service system:

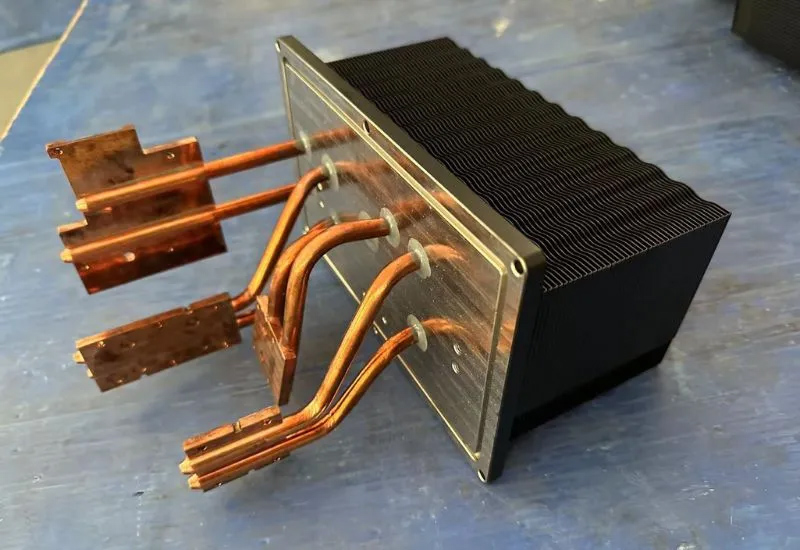

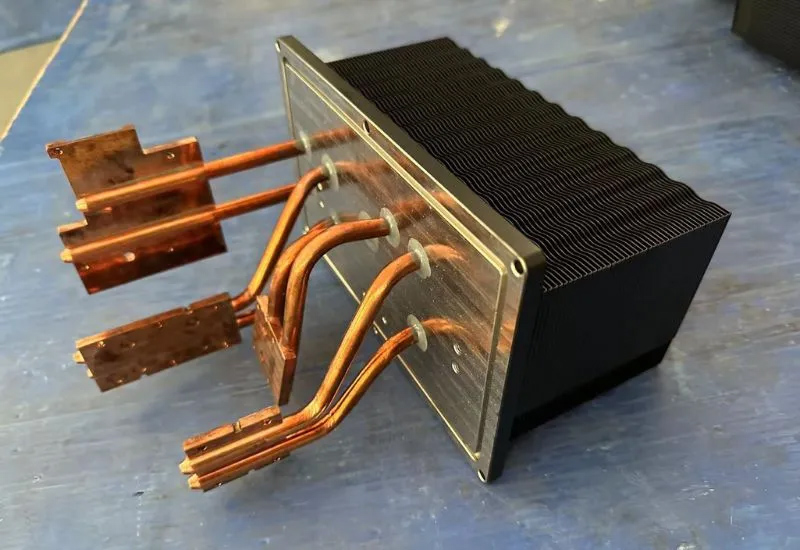

Strong customization capabilities

Kingka provides one-stop heat pipe customization services from design, sample proofing to batch manufacturing, supporting various shapes, lengths, power ranges, materials and working fluid combinations to meet the special heat dissipation needs of different scenarios.

Professional technical support

With an experienced thermal design team, we provide customers with technical support such as heat dissipation simulation analysis, heat pipe layout optimization, and structural selection recommendations to help customers improve product thermal efficiency.

Strict quality control

Adopt high-standard manufacturing processes such as vacuum reflow soldering, ultrasonic cleaning, nitrogen sealing, etc., and pass strict performance tests (start-up temperature test, thermal resistance detection, life evaluation) to ensure that each heat pipe is stable and reliable.

Rich industry experience

Kingka's heat pipe products have been widely used in 5G communication equipment, military radar, industrial inverter, laser, server, LED lighting, new energy vehicle battery pack and other fields, and have accumulated a lot of cross-industry thermal management experience.

Quick response delivery

The perfect production line and supply chain management support fast proofing and batch delivery, adapting to the customer's new product introduction and large-scale mass production rhythm.

If you are looking for an efficient and reliable heat pipe cooling solution, Kingka will be your trusted partner. Whether it is a compact electronic device or an aerospace system that requires stability in extreme environments, Kingka can provide you with a matching thermal management solution.