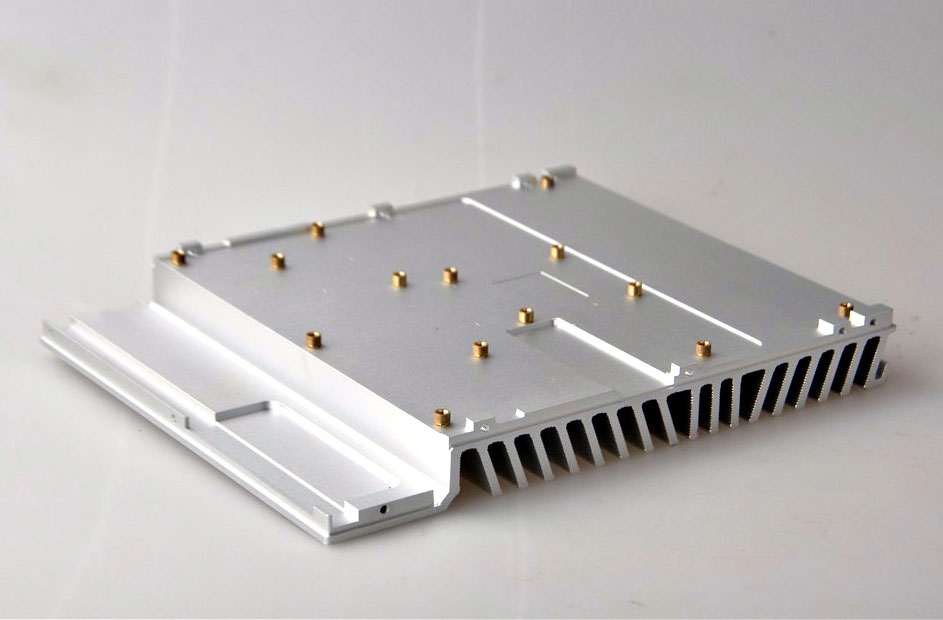

KingKa is a leading manufacturer of extruded aluminum heat sinks

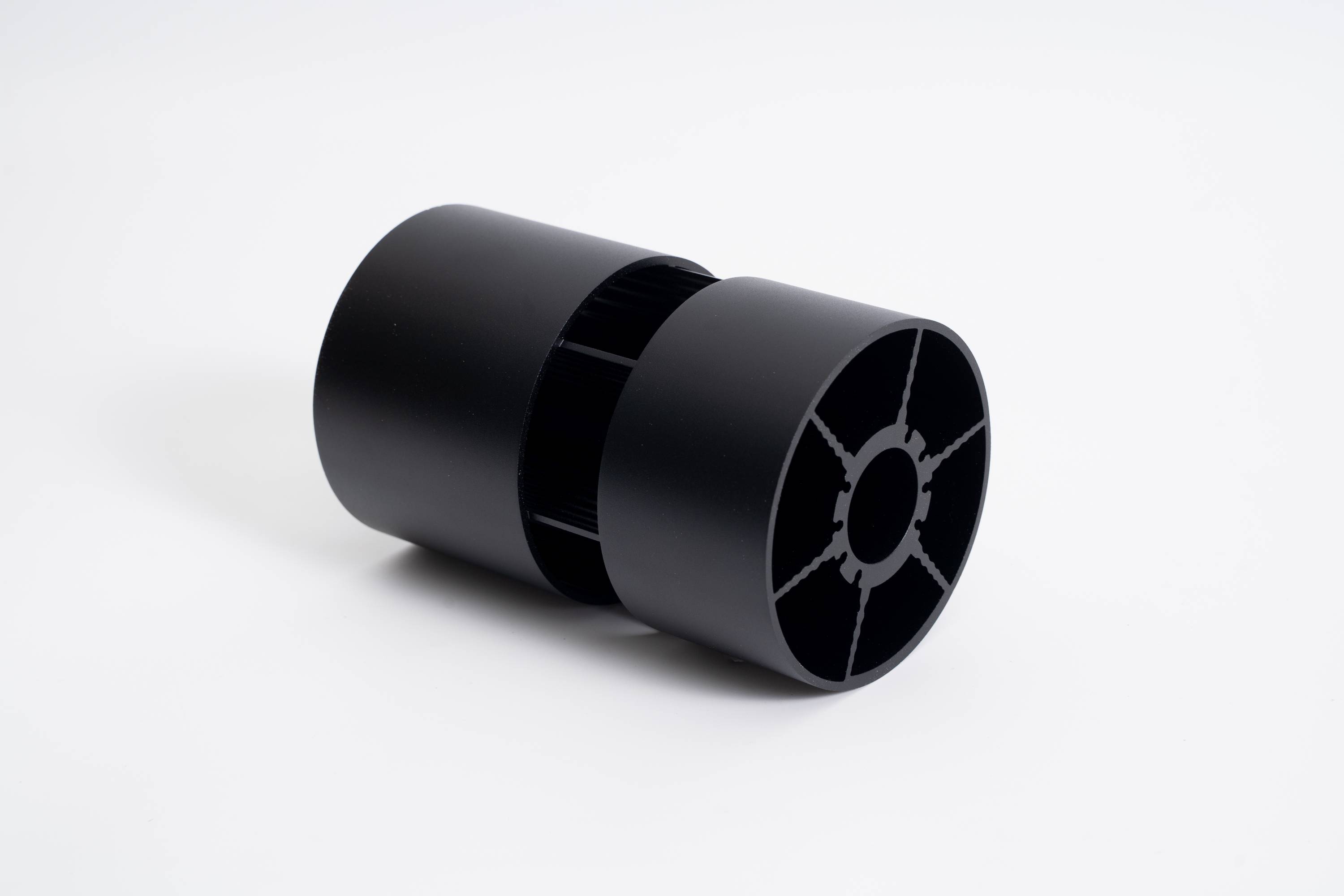

Offering a wide range of profiles designed for a variety of cooling applications. Whether natural or forced cooling, we have solutions that ensure optimal heat dissipation. From standard profiles to custom designed solutions, our extruded aluminum heat sinks meet a variety of industry requirements.

Our standard heat sinks

Include classic fin profiles, ideal for natural convection cooling, but also for forced air cooling systems. The profiles we offer range from small compact designs for transistor cooling to large options for high power devices such as IGBTs, with widths up to 900 mm.

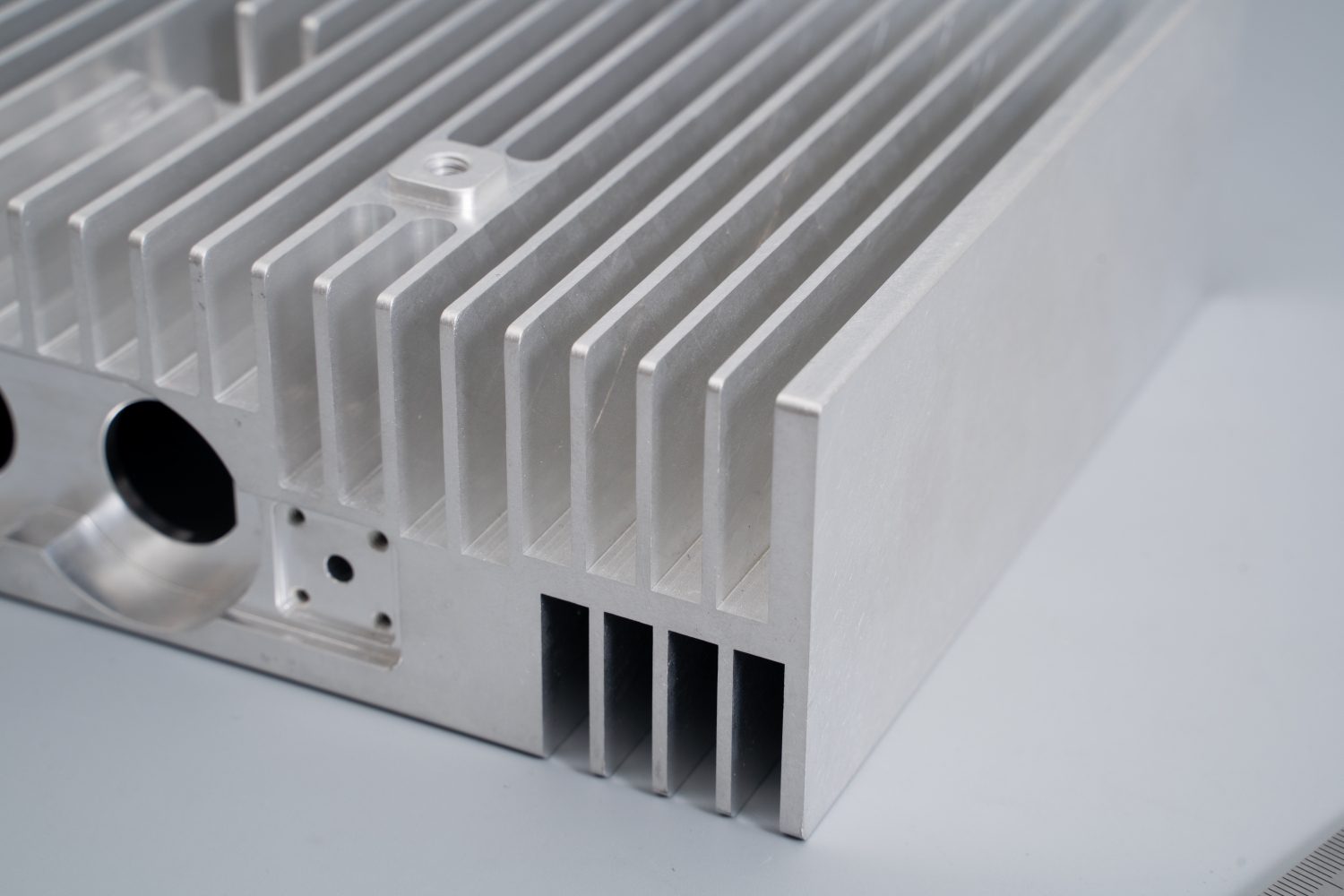

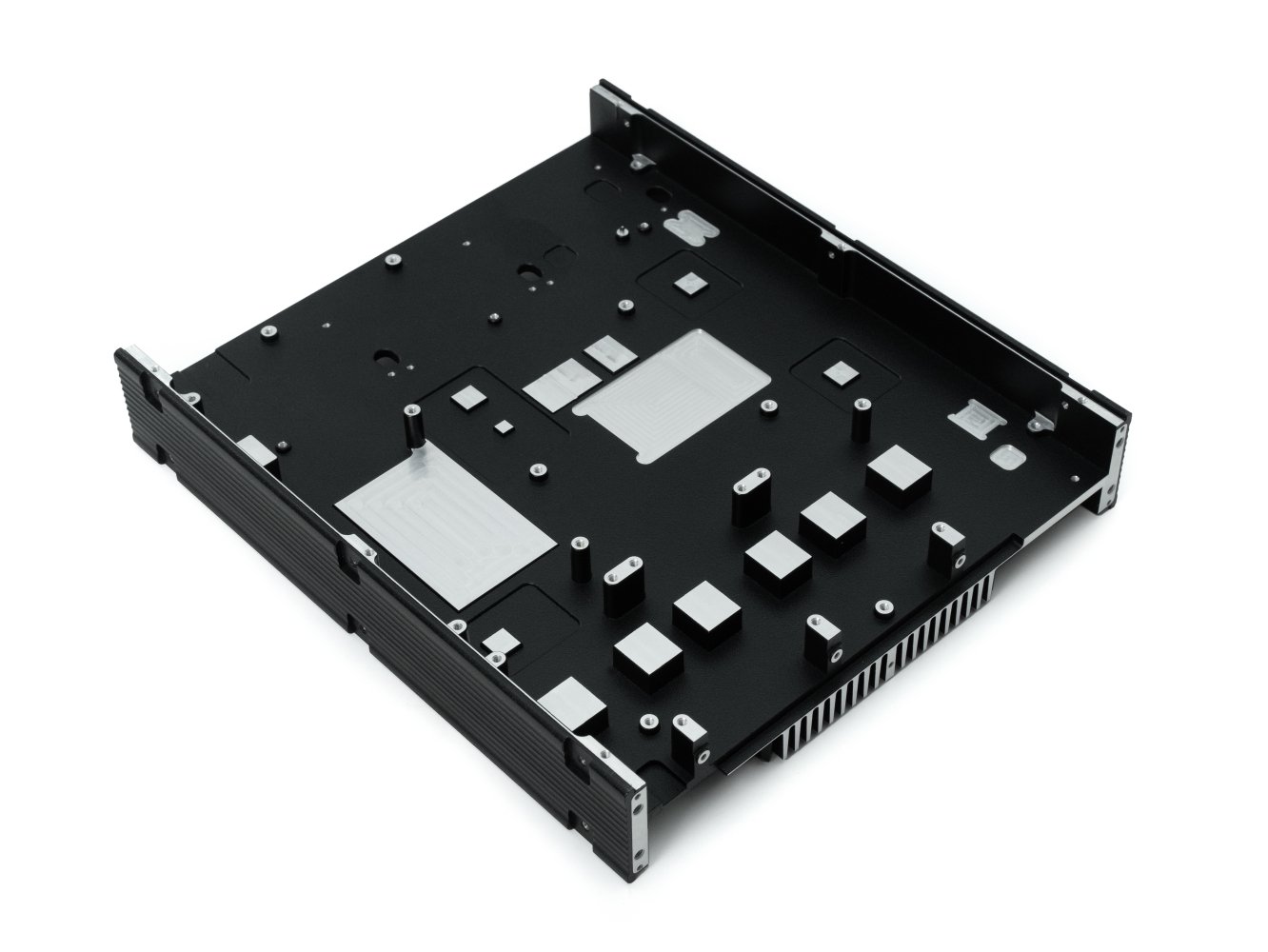

KingKa offers a wide range of profiles, including fins, profiles and liquid cooling options.

We offer modular profiles ranging from 5 mm to 60 mm in height and from 40 mm to over 400 mm in width. For special needs, we also specialize in custom configurations and tailor-made designs, ensuring efficient cooling and a precise fit for your components.

In addition to standard designs, we also offer advanced cooling solutions, including liquid cooled heat sinks, ideal for applications where air cooling is insufficient. Our liquid heat sinks can be customized with drawn or milled cooling channels for both small and large-scale production.

Our team is dedicated to providing the most efficient and cost-effective heat sink solutions. If our standard profiles don’t quite meet your needs, we will provide an affordable custom profile to your exact requirements, ensuring raw material efficiency and enhanced functionality. With KingKa, you get an exclusive custom solution that meets your application’s cooling needs.

For more details or to discuss your specific cooling requirements, please contact us today. We look forward to working with you to create the best heat sink solution for your product.