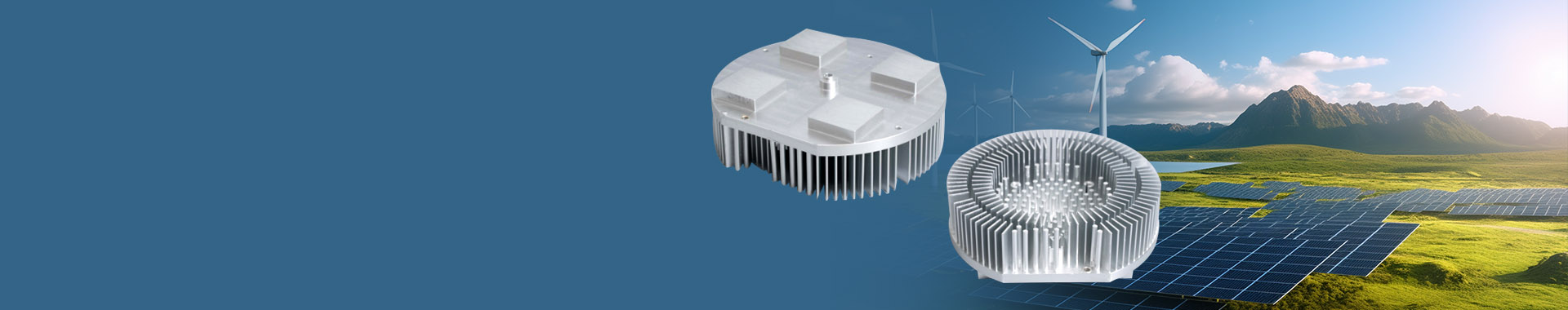

KINGKA specializes in customized solutions for cold forging heat sinks, which are widely used in electronics, automobiles, communications and other industries. The advantage of the cold forging process is its high-precision dimensional tolerance (±0.05mm) and surface roughness control above Ra 1.6, ensuring that the heat sink can provide excellent thermal conductivity. The thermal conductivity of the heat sink can reach 200-300 W/m·K, significantly improving the heat dissipation effect.

We offer a variety of material options, including aluminum alloy, copper, etc., with a tensile strength of up to 250 MPa, ensuring the stability of the heat sink under high temperature and high load environments.

In addition, customized heat sinks ranging from 30mm x 30mm to 200mm x 200mm can be provided according to the specific needs of customers to ensure that the needs of different applications are met.

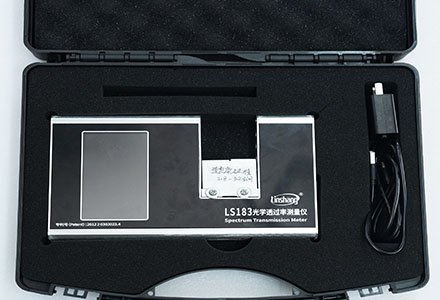

Our products comply with the ISO 9001 quality management system and are strictly tested by X-ray, ultrasonic and other methods to ensure that the quality of each batch of products is 100% qualified. With efficient production capacity, we can produce more than 50,000 cold forged heat sinks per month, and provide a small batch delivery cycle of 10-15 days to meet customers' urgent needs.

We have gained the trust of more than 200 customers worldwide, with a customer satisfaction rate of up to 98%. We are committed to providing customers with high-quality cooling solutions to ensure that every cooperation can be successfully achieved.